Composites Process Simulation: A Review of the State of the Art for Product Development - A283

| Composites Process Simulation: A Review of the State of the Art for Product Development | |

|---|---|

| Perspectives article | |

| |

| Document Type | Article |

| Document Identifier | 283 |

| Themes | |

| Tags | |

|

Webinar Date

| |

Introduction[edit | edit source]

A fundamental concept in materials science is that process history leads to microstructure evolution, which in turn determines mechanical and functional properties. For composite components, where the material is transformed at the same time as the component is created, the local process history is a function of the whole processing system which includes material(s), part shape, tooling, and equipment.

As both structural size and production scale up, controlling process history and hence microstructural and property evolution becomes progressively more difficult. In an ideal situation, every step of the process is well understood in terms of the underlying physics and can be simulated mathematically. The quality and breadth of, and confidence in these process simulations determines how they can be used. If low, they can be used as job-aids which are validated experimentally. If high, they might be used as part of the formal process validation and documentation.

Developing this type of capability is the current rage across all manufacturing industries, under the banner of Integrated Computational Materials Engineering (ICME), Industry 4.0, and the like. However, composites manufacturing processes are very complex, and there is a notable lack of data compared to other industrial sectors with much larger production volumes.

Although adoption of these new technologies has been slower than elsewhere, the last twenty years are showing accelerating adoption of process simulation in the aerospace composites sector. This webinar introduces process simulation, with a high-level assessment of the state of the art, and guidance on how it might be used as part of a product development approach.

Webinar[edit | edit source]

Webinar slides[edit | edit source]

Webinar slides available by clicking on the icon below

Additional information for select chapters[edit | edit source]

| Chapter | Chapter Title | Links to related information in the Knowledge in Practice Centre |

|---|---|---|

| 1 | Welcome & introductions | N/A |

| 2 | Review of composites processing & current practice | |

| 3 | Introduction to process simulation of composites | |

| 4 | Composites manufacturing as a systems problem | |

| 5 | Managing quality outcomes in the factory | |

| 6 | Maturation steps of process simulation | N/A |

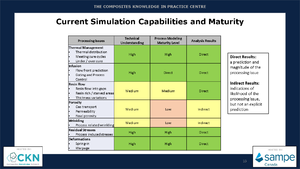

| 7 | Current simulation capabilities and maturity | Future content |

| 8 | Construction (materials deposition) simulation | Future content |

| 9 | Infusion simulation | |

| 10 | Consolidation and porosity simulation | Future content |

| 11 | Cure simulation |

|

| 12 | Cure simulation: Material characterization | |

| 13 | Cure simulation: HTC calibration | |

| 14 | Use of simulation to guide tooling decision making | |

| 15 | Use of optimization software in process simulation | Future content |

| 16 | Combined behaviour of equipment & tooling | |

| 17 | Science-based data analytics of production data | Future content |

| 18 | Residual stress & process induced distortion sim. | |

| 19 | Linking process sim. to residual stress & failure | Future content |

| 20 | Comparing dimensional experiments & models | Future content |

| 21 | Validating distortion process models in development | Future content |

| 22 | Summary & wrap-up | N/A |

| 23 | Q&A | N/A |

Related pages

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.