Porosity in Composite Materials - Part II - A337

| Porosity in Composite Materials - Part II | |

|---|---|

| Perspectives article | |

| |

| Document Type | Article |

| Document Identifier | 337 |

| Themes | |

| Tags | |

| Prerequisites | |

|

Webinar Date

| |

Introduction[edit | edit source]

Composite materials inherently contain defects, which introduce variability and often restrict their mechanical properties. Among these defects, porosity is one of the most prevalent and can negatively affect both the structural integrity and aesthetics of the material. The presence and extent of porosity are largely determined by processing parameters.

Previously (see recording here), we presented a comprehensive list of common causes of porosity along with considerations for reducing or eliminating them (Sources and sinks). In this webinar, we continue to investigate the sources and sinks of porosity, particularly focusing on liquid composite molding and advanced manufacturing techniques such as prepreg and out-of-autoclave prepreg processing. We also delve into the formation of porosity within these processes and present case studies. Critical steps like debulking and degassing will be thoroughly discussed. Additionally, we provide an overview of the methodologies for measuring and assessing the levels of porosity in a manufactured composite component.

This presentation is part of CKN’s ongoing Application + Impact (AIM) webinar series. Content discussed in the webinar is linked to the Knowledge in Practice Centre, allowing users to access this and other content in a consistent and coherent manner.

Presenter[edit | edit source]

Dr. Casey Keulen

Assistant Professor of Teaching, Department of Materials Engineering, The University of British Columbia

Director, CKN Knowledge in Practice Centre

Gavin Tao, M.A.Sc.

Research Engineer, Composites Research Network, Materials Engineering, The University of British Columbia

Webinar[edit | edit source]

Webinar slides[edit | edit source]

Webinar slides available by clicking on the icon below

Additional information for select chapters[edit | edit source]

| Chapter | Chapter Title | Links to related information in the Knowledge in Practice Centre |

|---|---|---|

| 1 | Welcome & introductions | N/A |

| 2 | Knowledge in Practice Centre | |

| 2 | Overview | |

| 3 | Introduction | |

| 3 | Sources and sinks | |

| 4 | Manufacturing processes | |

| 4 | Source: Tool/Bag/Vacuum leaks | |

| 5 | Source: Outgassing | |

| 5 | Storage and handling of prepreg materials | |

| 6 | Source: Moisture dissolved in resin | |

| 6 | Degassing of resin | |

| 7 | Degassing: Bubble nucleation | |

| 7 | Degassing: Effect of temperature | |

| 8 | Degassing: Effect of hydrostatic pressure | |

| 8 | Degassing: Effect of agitation | |

| 9 | Removing porosity sources by debulking | |

| 9 | Porosity due to resin flow and fibre infiltration | |

| 10 | Gas transport inside laminate | |

| 10 | Resin flow - Impregnation mechanisms | |

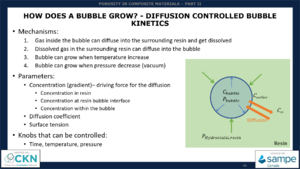

| 11 | Parameters affecting gas transport | N/A |

| 11 | Kinetics of bubbles | N/A |

| 12 | Assessing/Measuring porosity | N/A |

| 12 | Summary & wrap-up | N/A |

| 13 | Q&A | N/A |

Related pages

| Page type | Links |

|---|---|

| Introduction to Composites Articles | |

| Foundational Knowledge Articles | |

| Foundational Knowledge Method Documents | |

| Foundational Knowledge Worked Examples | |

| Systems Knowledge Articles | |

| Systems Knowledge Method Documents | |

| Systems Knowledge Worked Examples | |

| Systems Catalogue Articles | |

| Systems Catalogue Objects – Material | |

| Systems Catalogue Objects – Shape | |

| Systems Catalogue Objects – Tooling and consumables | |

| Systems Catalogue Objects – Equipment | |

| Practice Documents | |

| Case Studies | |

| Perspectives Articles |

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.