Debulking - P167

| Debulking | |

|---|---|

| Practice document | |

| Document Type | Practice |

| Document Identifier | 167 |

| Themes | |

| Tags | |

| Prerequisites | |

Introduction[edit | edit source]

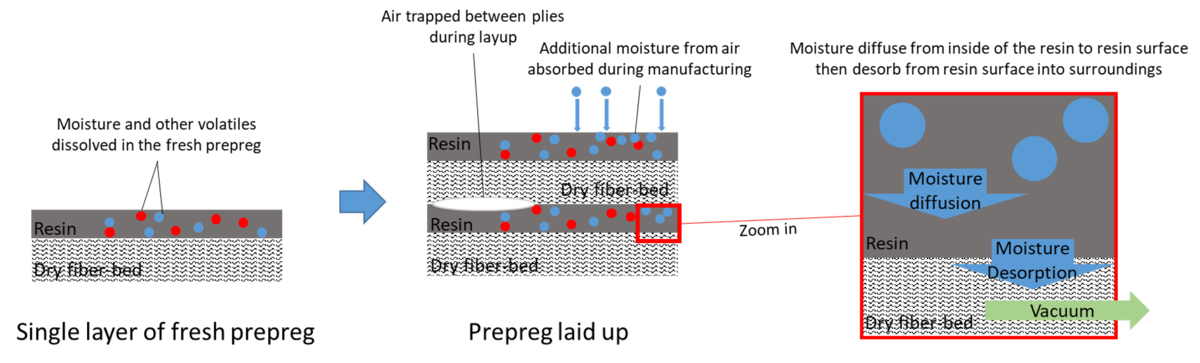

Debulking, referring to holding an un-cured layup under vacuum for a period of time, is a common practice for composite parts made from prepreg. The laminate is typically de-bulked every 3-5 layers for 5-15 minutes depending on the shape complexity. The purpose of this is to consolidate the laminate and remove entrapped air between the prepreg plies while conforming/consolidating the plies to the tool. Debulking can also be perform at elevated temperatures to soften the resin for better consolidation[1]. Debulking can remove some moisture dissolved in the resin which leads to less bubbles and porosity in the final part[2]. The term "debulking" is also used sometimes with liquid composite moulding where the dry reinforcements is compacted prior to matrix deposition.

Significance[edit | edit source]

Debulking can remove air, moisture and volatiles from the laminate, which is critical in managing the porosity level in the final part. Air pockets, evaporating moisture and outgassing volatiles can act as nucleation cites for porosity to develop during cure. Debulking also helps to consolidate the plies down on to the tool, which can result in less wrinkles and/or waviness in the final part. Debulking is especially important for parts made from out-of-autoclave (OOA) prepreg materials. OOA parts are more susceptible to porosity because vacuum is only source of compaction/consolidation pressure.

Scope[edit | edit source]

This page discusses how debulking removes air and moisture from the composite laminate before thermal transformation. Mechanisms such as diffusion and sorption during debulking are described. Different parameters that can affect debulking effectiveness, such as time, temperature, and part size and complexity are explained. Debulking has different implications when used in liquid composite moulding vs prepreg. A section is dedicated to the specific processes and implications. Equipment used for debulking are also mentioned.

How does debulking work[edit | edit source]

A room temperature debulking setup is similar to that of the vacuum bagging arrangement used during the curing process. A vacuum bag covering the part is connected to a vacuum source. Peel ply and breather cloth are used to provide air and volatile passage to the entire part surface, allowing for uniform vacuum pressure. When the vacuum is applied, there is a pressure gradient between the gas that was initially in the laminate and the reduced gas pressure from the vacuum source which drives the gas evacuation.

Later in the debulking process, when most of the air has been removed, the reduced gas pressure surrounding the resin droplets also promote desorption of the volatiles within the resin. The volatiles can be air, moisture and other low molecular chemical compounds dissolved in the resin as part of the resin formulation. (See degassing for more on desorption mechanisms in liquid resin.) Before vacuum is applied, the moisture content within the resin and the gas surrounding it are in equilibrium. When the vacuum is applied, the reduced gas pressure reduces the moisture concentration surrounding the resin. The difference in moisture concentration (i.e. concentration gradient) helps drive the moisture out of the resin. The amount of moisture being extracted by debulking depends on the vacuum pressure, debulking temperature, part shape & size and duration. In general:

- Better vacuum levels facilitates more moisture extraction. Its not uncommon to see areas closer to the vacuum port with lower moisture content than areas far away from the port

- Elevated temperature facilitates more moisture extraction given the temperature is not high enough to advance resin cure and resin viscosity to increase. See remarks on hot debulk below

- The more complex part shape and the larger the part size, the longer it takes for moisture extraction

- The longer debulking lasts, the more moisture content can be extracted. The moisture extraction rate will slow down as debulking goes on.

The above mentioned parameters also apply to removing air. In other words, the overall effectiveness of debulking increase with better vacuum level, higher temperature (to a certain extend), smaller part size and longer debulking time. Debulking for a long time can add significant cost to the manufacturing process. Not to mention the fact that vacuum leaks happen often. Therefore the complete extraction of moisture during debulking is not practical. In other words, there will always be remaining moisture content in the laminate during the subsequent cure.

In addition to removing volatiles from the laminate, debulking plays a major role in consolidating the fibre bed on to the tool such that it takes the shape of the tool. This reduces loftiness which could later manifest as wrinkling or waviness when the laminate is put under a vacuum bag to cure. This is typically caused by the mismatch in travel between a stack of plies as they traverse a radius - plies on the inside have a shorter distance to travel, while plies further out have a longer distance. Debulking consolidates the plies, removes 'bulk' or loftiness and helps adhere to the tool.

Remarks on hot debulk[edit | edit source]

Resin flow/infiltrating into the dry fiber-bed and resin cure advancement are two major concerns when performing a hot debulk. At room temperature, even with extremely long debulk times(on the order of days), there is usually little resin flow because the resin in prepreg are designed with high viscosity at room temperature. Resin in OOA prepreg typically have even higher viscosity than the resin in autoclave cured prepregs at room temperature[3]. However, resin viscosity drops with increasing temperature. When a laminate is heated for hot debulking, the resin can potentially flow into the dry fiber-bed prematurely and close the engineered vacuum channels, preventing further gas evacuation.

Depending on the debulking temperature, the degree of cure of the resin in the prepreg may potentially advance. The advancement in cure can increase the resin viscosity leading to undesired resin flow behavior during the subsequent curing process.

If more compaction is required, the debulking can be performed using an autoclave. More pressure (up to around 90 psi) in addition to vacuum pressure can be applied to the laminate, providing extra consolidation while heating. Autoclave debulking can be used when the laminate needs to be as compact as possible before curing, such as for some match-die moulding applications. The additional step of pressurization are usually costly and time consuming.

Debulking in liquid composite moulding[edit | edit source]

Controlled atmospheric pressure resin infusion (CAPRI) is a variant of the vacuum-assisted resin transfer molding (VARTM) process patented by the Boeing Company[4]. CAPRI involves debulking the dry reinforcement before infusing the resin, aiming to increase part fibre volume fraction and thickness consistency. The compacted dry reinforcement was shown to have more consistent thickness along the resin flow path. [5] However, the compacted reinforcement has lower permeability which can increase infusion time. A study also showed significant increase in void content and size when the dry reinforcement is debulked before infusion. It is believed that the tight packing of the fiber made it more difficult for resin to permeate through. [6]. Because of this, the CAPRI process calls for partial vacuum during the infusion process. The lower pressure gradient across the resin inlet and outlet drives a slower resin flow, which gives more time for resin to permeate through the reinforcement. Although CAPRI can produce parts with high fiber volume fraction and better thickness consistency compared to the conventional VARTM, the additional debulking step and slower resin infusion speed required can increase the production time.

Equipment for debulking[edit | edit source]

Maturity[edit | edit source]

Debulking is a very common practice, hence the knowledge is mature. The underlying scientific knowledge regarding gas transport mechanisms, resin flow and fiber-bed compaction is well established. Existing models can predict the debulking time scale and amount of moisture extraction.[3] The consequences of what happens during debulking in the subsequent curing and manufacturing outcomes are also well understood.

Related pages

| Page type | Links |

|---|---|

| Introduction to Composites Articles | |

| Foundational Knowledge Articles | |

| Foundational Knowledge Method Documents | |

| Foundational Knowledge Worked Examples | |

| Systems Knowledge Articles | |

| Systems Knowledge Method Documents | |

| Systems Knowledge Worked Examples | |

| Systems Catalogue Articles | |

| Systems Catalogue Objects – Material | |

| Systems Catalogue Objects – Shape | |

| Systems Catalogue Objects – Tooling and consumables | |

| Systems Catalogue Objects – Equipment | |

| Practice Documents | |

| Case Studies | |

| Perspectives Articles |

References

- ↑ [Ref] Campbell, F.C. (2004). Manufacturing Processes for Advanced Composites. Elsevier. doi:10.1016/B978-1-85617-415-2.X5000-X. ISBN 9781856174152.CS1 maint: uses authors parameter (link) CS1 maint: date and year (link)

- ↑ [Ref] Mohseni, Mohammad (2020). Experimental Study and Analytical Approaches to Avoid Matrix Defects during Composites Manufacturing (Thesis). doi:10.14288/1.0389729.CS1 maint: uses authors parameter (link)

- ↑ 3.0 3.1 [Ref] Kay, James (2017). Gas transport and void evolution in composite prepregs (Thesis). doi:10.14288/1.0357202.CS1 maint: uses authors parameter (link)

- ↑ [Ref] WO2003101708A1, Andrew E. Modin, "Controlled atmospheric pressure resin infusion process", published 2003

- ↑ [Ref] Niggemann, Christian et al. (2008). "Experimental Investigation of the Controlled Atmospheric Pressure Resin Infusion (CAPRI) Process". 42 (11). doi:10.1177/0021998308090650. ISSN 0021-9983. Cite journal requires

|journal=(help)CS1 maint: extra punctuation (link) CS1 maint: uses authors parameter (link) - ↑ [Ref] Schey, Mathew et al. (2023). "Effects of debulking on the fiber microstructure and void distribution in carbon fiber reinforced plastics". 165. Elsevier Ltd. doi:10.1016/j.compositesa.2022.107364. ISSN 1359-835X. Cite journal requires

|journal=(help)CS1 maint: extra punctuation (link) CS1 maint: uses authors parameter (link)

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.