Resin degassing - P166

| Resin degassing | |

|---|---|

| Practice document | |

| Document Type | Practice |

| Document Identifier | 166 |

| Themes | |

| Tags | |

| Prerequisites | |

Introduction[edit | edit source]

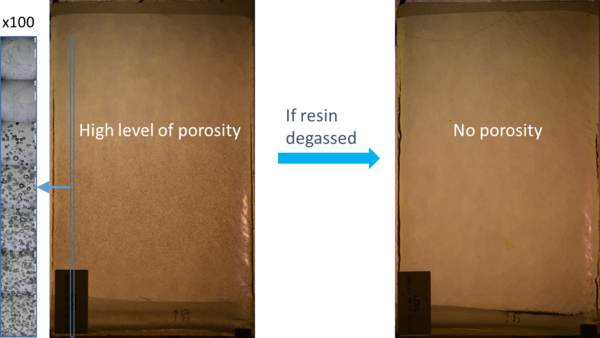

Resin degassing, which involves holding liquid resin under vacuum to remove entrapped volatiles is a common practice for liquid composite moulding. Entrapped volatiles can become bubbles within resin during processing. The removal of volatiles ultimately leads to a reduction in porosity within the part.

Significance[edit | edit source]

Degassing is an important step for any composite manufacturing process that involves liquid resin. For example, degassing is recommended prior to wet layup, resin infusion, resin transfer moulding, resin injection moulding, spray up and filament winding. Resin degassing is also a critical step before impregnating prepreg during prepreg manufacturing. Effective degassing before depositing the resin is critical for meeting porosity requirements and quality specifications.[1]

Scope[edit | edit source]

Successful degassing involves using vacuum to remove volatiles, entrapped air and moisture from the liquid resin. It is important to differentiate degassing from de-bulking, which implies drawing vacuum on the un-cured layup to conform/consolidate the plies to the tool and remove entrapped air or gases. De-bulking is typically performed on dry reinforcements or pre-preg whereas degassing is conventionally used with liquid resin.

On this page, we will discuss what the composition of the volatiles and the mechanisms for removing them during degassing (i.e. how does resin degas). Parameters for degassing such as time, temperature and hydrostatic resin pressure will be discussed. Equipment needed and common practice for degassing will also be covered.

Analysis[edit | edit source]

What is degassing intended for?[edit | edit source]

Parts made with liquid composite moulding (LCM) processes may contain porosity. One of the sources for porosity is resin outgassing - volatiles coming out of the resin and remaining present in the gas state during processing. Under vacuum conditions, the effect is exaggerated such that a small amount of outgassed elements can result in a large amount of porosity. Degassing aims to remove those elements before the resin cures with the goal of reducing porosity.

Other sources for porosity in liquid composite moulded parts include: tool/bag leakage, air entrapment at the flow front, inadequate resin flow rate, etc., as explained here.

What elements typically degas and where do they come from?[edit | edit source]

Air, moisture and volatiles can outgas during processing and cure.

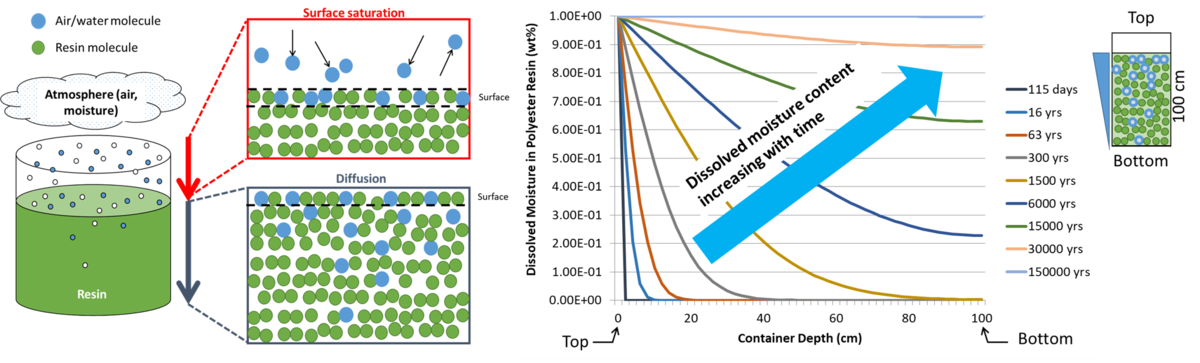

Over the life of the liquid resin, although very slowly, air and water molecules can saturate the surface of the resin, which creates a concentration gradient. The gradient then drives the diffusion through the resin volume towards the bottom of the container. Air and moisture can also be entrapped during the resin manufacturing process and the mixing process.

At 100%RH, polyester resin can absorb up to 0.5wt% to 1wt% water[2]. Although it does not seem like much, under vacuum conditions, water can vaporize into ~8X the volume of liquid water in the resin.

Volatiles can also be the low molecular weight compound that is part of the resin formulation such as solvents or by-products from resin curing.

How does resin degas?[edit | edit source]

The common method for resin degassing involves applying vacuum to an air-tight vessel that holds the liquid resin to be degassed. Typically, bubbling will be observed during degassing. If we look closely, the bubbles will go through a nucleation and growth stage before they rise to the resin surface and escape from the resin.

The second gas transport mechanism is diffusion. Just like concentration gradient, which drove the air and water molecules into the resin, when the resin is under vacuum, the molecules can diffuse outwards. However, gas and moisture removal via diffusion is very slow under vacuum. It is not practical for typical part production. This leaves bubbling as the main mechanism.

What affects the resin degassing rate?[edit | edit source]

To facilitate/initiate the bubble nucleation, a porous media such as a piece of Scotch-brite can be placed in the the resin. The larger surface area of the porous media provides a substrate for the bubbles to nucleate (heterogeneous nucleation) as opposed to bubbles nucleating from the resin volume (homogeneous nucleation). Homogeneous nucleation requires more energy compared to heterogeneous nucleation. Using a container that has a rough surface (plastic) is more effective than a container with a smooth surface such as glass, for the same reason.

Temperature and resin hydrostatic pressure are two important parameters that can affect the degassing rate. An increase in temperature can lower the resin viscosity, making bubbles rise to the surface faster. Because the rate of bubble growth is dependent on the diffusion rate, at higher temperature, molecules can diffuse through the resin faster and form into a bubble. Higher temperature comes with higher bubble growth rates.

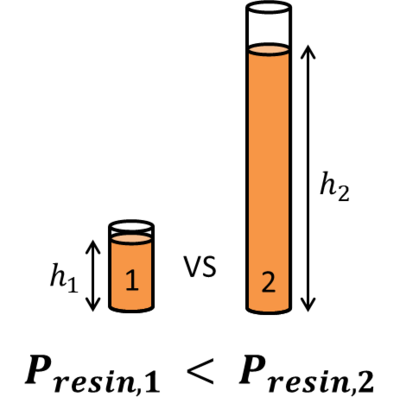

For the bubbles to grow, the pressure inside the bubble (vapor pressure) needs to be higher than the pressure of the resin around it (resin hydrostatic pressure). The easiest way to decrease hydrostatic pressure is by applying vacuum. In some situations, even with vacuum, resin can still have significant levels of hydrostatic pressure. For example, consider a deep barrel of resin. Due to the weight of resin, the pressure at the bottom of the barrel is considerably higher than near the surface, which means the resin at the bottom cannot be effectively degassed. Thus, whenever possible, resin should be degassed in large, shallow volumes.

To further speed up the degassing process, an agitator/mixer can be used to stir the resin. The mixer can also bring the resin from the bottom of the container to the surface where the hydrostatic pressure is less, so the bubbles can form and escape more rapidly.

When to degas the resin and when not to?[edit | edit source]

During composite manufacturing, degassing is performed before the liquid resin is deposited into the mould. Resin components (part A and part B) can be degassed either before mixing, after mixing or both. Degassing before mixing usually aims to remove the air, moisture and volatiles absorbed into the resin during storage and resin manufacturing. Degassing after mixing can further remove the air introduced during mixing and volatiles generated from the chemical reaction. During mixing, air can be easily mixed into the resin which can later serve as nucleate sites for porosity and voids. Caution needs to be taken when degassing after mixing to make sure the resin's pot life (gel time) is longer than the degassing time plus the time needed for deposition. Typically, resin is degassed for 10 - 15 minutes under full vacuum but this is a function of the variables discussed above.

Depending on the application, some polymers do not benefit from degassing (such as some thick two part epoxy, two part urethane, silicone etc.). Those polymers typically have very high viscosity. Although bubbles can still nucleate within those materials but the bubbles can not float/migrate to the top surface and escape. Sometimes the material will not have enough flow to collapse the bubbles formed by degassing and eventually trapping more bubbles. In those cases, the material is better off left un-degassed. Whenever possible, follow manufacturer's instruction for degassing and processing materials.

Tips for degassing[edit | edit source]

- A see-through vacuum chamber can provide insight into what is going on with the resin under vacuum

- Because resin "boils" under vacuum, a large container inside the vacuum chamber may be used to prevent resin overflow. The analogy of pouring a carbonated drink into a class, where it bubbles up and overflows is apt.

- Release the vacuum slowly after degassing is finished. Depending on where the vacuum chamber inlet valve is, sometimes the air gushing in can blow the resin all over the vacuum chamber

- A typical degassing process would go as follows:

- Liquid resin (part A, part B, or mixed) in a container (cup/bucket) is placed in a vacuum chamber with consideration for resin bubble over (ie. either an oversized container for the volume of resin or a secondary container to catch the overflow)

- Porous media (Scotch-brite pad) may be added to promote nucleation

- The vacuum chamber with resin may or may not be placed in an oven to increase temperature

- Vacuum is pulled on the chamber and held for ~10-15 minutes depending on the variables discussed above

- Vacuum is slowly vented such that incoming air does not adversely affect the resin (ie. blow the resin out of the container)

- Resin is removed from the chamber and processed

Equipment for degassing[edit | edit source]

Typical equipment needed for degassing are:

- Vacuum pump

- Vacuum chamber

- Specialty degassing chamber

- Oven

- Porous media (Scotch-brite pad)

Maturity[edit | edit source]

Degassing is a very common practice, hence the knowledge is mature. The underlying scientific knowledge regarding gas transport mechanisms, bubble nucleation and growth and hydrostatic pressure is well established.

Related pages

| Page type | Links |

|---|---|

| Introduction to Composites Articles | |

| Foundational Knowledge Articles | |

| Foundational Knowledge Method Documents | |

| Foundational Knowledge Worked Examples | |

| Systems Knowledge Articles | |

| Systems Knowledge Method Documents | |

| Systems Knowledge Worked Examples | |

| Systems Catalogue Articles | |

| Systems Catalogue Objects – Material | |

| Systems Catalogue Objects – Shape | |

| Systems Catalogue Objects – Tooling and consumables | |

| Systems Catalogue Objects – Equipment | |

| Practice Documents | |

| Case Studies | |

| Perspectives Articles |

References

- ↑ [Ref] Campbell, F.C. (2004). Manufacturing Processes for Advanced Composites. Elsevier. doi:10.1016/B978-1-85617-415-2.X5000-X. ISBN 9781856174152.CS1 maint: uses authors parameter (link) CS1 maint: date and year (link)

- ↑ [Ref] Dhakal, H. N. et al. (2007). "Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites". 67 (7–8). doi:10.1016/j.compscitech.2006.06.019. ISSN 0266-3538. Cite journal requires

|journal=(help)CS1 maint: extra punctuation (link) CS1 maint: uses authors parameter (link)

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.