Consolidation of Thermoplastics - P170

| Consolidation of Thermoplastics | |||||||

|---|---|---|---|---|---|---|---|

| Practice document | |||||||

| |||||||

| Document Type | Practice | ||||||

| Document Identifier | 170 | ||||||

| Themes | |||||||

| Tags | |||||||

| Objective functions |

| ||||||

| MSTE workflow | Development | ||||||

| Prerequisites | |||||||

Overview[edit | edit source]

The page covers a brief overview of consolidation processing of thermoplastics, including the mechanics behind the process and some of the equipment choices available for a consolidation process.

Introduction[edit | edit source]

Thermoplastic consolidation is a crucial part of creating a final product in order to dictate the final properties and shape of the part. Consolidation requires elevated temperature, applied pressure, and time, These parameters vary depending on the material type, form and shape, but the basics are the same across most thermoplastics. Temperature, pressure and time allow for the diffusion of polymer chains in order to create a cohesive part.

Significance[edit | edit source]

Consolidation of thermoplastics is a critical step in the fabrication of composite parts. This process ensures that the individual layers of thermoplastic materials, such as prepregs or films, are effectively bonded together to form a strong and cohesive structure. The consolidation process not only ensures the mechanical integrity of the final product but also enhances its thermal and chemical resistance properties.

Processing[edit | edit source]

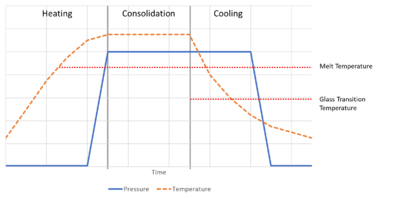

Consolidation of thermoplastics consists of heating, applying pressure and cooling, refer to the image on the left for an example of a process cycle. Just like with other kinds of composite materials, the main things that affect how this process works are how long it takes (time), how hot it gets (temperature), and how much pressure is applied. Heating the thermoplastics can be done with a variety of different options like: infrared ovens, convection ovens, hot presses, and autoclaves. The time required to reach consolidation temperature depends on only the heating method, mass of material and mass of the tooling because there are no chemical reactions occurring.

The temperature needed for consolidation depends on the type of thermoplastic being used in the process. For thermoplastics that are amorphous, they need to be heated to above their Glass transition temperature (Tg). For semi-crystalline thermoplastics, they need to reach temperatures above their melting temperature to achieve consolidation. As a rule, if you're working with an amorphous thermoplastic, you should aim for a processing temperature 220°C above its glass transition temperature, and for a semi-crystalline one, it should be about 100°C or less above its melting point. But degradation can occur by heating most thermoplastics above 425°C[1].

The amount of time needed for consolidation at a certain temperature mostly depends on the form of the thermoplastic. For instance, if a well-consolidated hot-melt impregnated tape is being used, it can be consolidated successfully in very short periods, sometimes just minutes or even seconds, because the resin melts quickly and spreads through the material easily. However, materials like woven powder coted or comingled prepregs need more time for the resin to melt and spread through the fibers. Sometimes, a technique called film stacking is used, where layers of thermoplastic film and dry woven cloth are stacked and pressed together. In these cases, consolidation takes even longer because the highly viscous resin has to travel further through the layers to fully impregnate the fabric.

A typical processing cycle to ensure that the fibers are completely impregnated and the laminate is fully consolidated when using film-stacked layers would involve applying a pressure of 150 psi for 1 hour. Similar to the heating process, cooling rate after consolidation depends on the method used for processing and the mass of the tooling. However, it's important not to cool down semi-crystalline thermoplastics too rapidly (known as quenching) because doing so might prevent them from forming the desired semi-crystalline structure, which is crucial for optimal performance at high temperatures and resistance to solvents[1].

While cooling, it is necessary to maintain pressure until the temperature drops well below the glass transition temperature (Tg) of the resin. This helps prevent the formation of voids, delays elastic recovery in the fibres, and preserves the desired dimensions of the final product.

Lastly, the applied pressure during the consolidation process provides the driving force for the fibre to become impregnated with the resin and provide the shape of the part. It is important to note that the properties achieved by prepreg that has been hot-melt impregnated is generally higher than the properties seen by powder coated, comingled and film stack laminates. This is due to the fiber-to-matrix bond that is formed during the hot-melt impregnation process.

For more see Introduction to the processing of thermoplastic composites

Mechanics[edit | edit source]

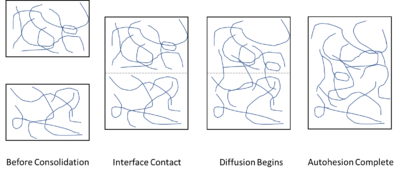

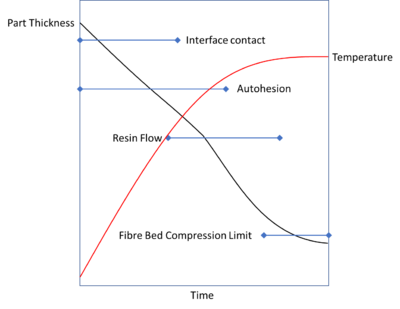

Thermoplastic consolidation happens through a process known as autohesion. This means that when two surfaces meet, they need to come into intimate contact before the polymer chains can spread across the boundary and achieve full consolidation. Because thermoplastic prepregs don't flow easily and can have uneven thicknesses, the surfaces need to be physically pressed together and heated up to ensure they are close enough for the polymer chains to move between them effectively. This process creates the right conditions for the chains to bond at the interfaces between layers, see figure to the left.

To achieve intimate contact and autohesion, the material needs to be heated above its glass transition temperature (Tg) for amorphous materials and above its melting temperature (Tm) for semi-crystalline materials. Typically, using higher pressures and temperatures can shorten the time needed for consolidation[1]. Autohesion involves a diffusion-controlled process where the polymer chains migrate across the interface and intertwine with nearby chains. As the contact time between the surfaces increases, more polymer chains become entangled, creating a stronger bond at the interfaces between layers.

For amorphous thermoplastics, consolidation generally takes more time due to the fact that the resin does not melt and maintains a higher viscosity. This can be somewhat mitigated by using higher pressures to force the movement of the resin. A thermoplastic must be pressed together to some extent before autohesion can occur, this is due to the fact that the time required for autohesion is directly proportional to the resin viscosity. The consolidation process is considered complete when the fiber bed is compressed enough to react to the pressures applied, see figure below.

Equipment[edit | edit source]

There are many forms and types of equipment that can be used to consolidate thermoplastics. The following will highlight some of the common equipment and the main considerations when using them.

Platen press[edit | edit source]

This process typically uses a hand lay up of the thermoplastic prepreg sheets, which are preheated in an oven before being placed in a press with a die for the final shape of the part. Since it is a hand layup, a soldering iron is sometimes used to hold/tack the sheets together as they have no tack at room temperature. The platen press can be heated and then cooled down, maintaining pressure for a successful consolidation. If the time at pressure for a specific prepreg is very low, then the platens may not be heated and the consolidation process and cooling can happen at the same time. A similar process to this can be done with rolling belts, instead of platens, with a heating and cooling zone can be used for continuous processes.

see Hot press

Extrusion and Injection molding[edit | edit source]

Through the use of an Archimedes screw and different heating stages, this process applies pressure and heat to the thermoplastic as it is moved along the length of the machine. The screw gradually applies pressure to the material and can be designed in different ways to provide pressure at different rates and sections of the screw. The material is moved through heated sections to begin the autohesion process. For an extrusion process, the material needs to be fully consolidated before exiting the screw as that is the final stage before a cooling die. For an injection molding process, the material needs to be partially consolidated before entering the mold, but some pressure and consolidation effects can be applied in the mold as well.

also see Pultrusion of Thermoplastic Composites

Autoclave[edit | edit source]

For complex part configurations, autoclave consolidation is an option, however, it has drawbacks. It can be challenging to find autoclaves capable of reaching the high temperatures (about 340-400°C) and pressures (about 100-200 psi) needed for some advanced thermoplastics. Also, the tooling required for such high temperatures is expensive and often large, leading to slow heating and cooling rates. Matching the coefficient of thermal expansion between the tool and the part is crucial, typically using materials like monolithic graphite, cast ceramic, or Invar 42 for carbon fiber thermoplastics.

Bagging materials must withstand high temperatures and pressures, typically requiring high-temperature polyimide bagging materials, glass bleeder cloth, and silicone bag sealant. Polyimide materials like Kapton or Uplilex are brittle and more challenging to work with compared to nylon materials used for lower temperature thermosets. High-temperature silicone rubber sealants have minimal tack at room temperature, requiring clamped bars to help seal effectively.

A typical autoclave consolidation cycle for carbon/PEEK prepreg involves temperatures of 360-399°C and pressures of 50-100 psi for 5-30 minutes, but the actual cycle time to heat and cool large tools is usually 5-15 hours. Despite these drawbacks, autoclaves remain useful for fabricating thermoplastic composite parts that are too complex for other methods[1].

see Autoclave

Auto-placement[edit | edit source]

Auto-placement or in situ placement, involves immediately consolidating the material into the layer below through directed heat and pressure. This includes processes such as hot tape laying, filament winding and automated fibre placement. Two common ways in which heat is applied to the part is through conductive heating from blocks of heated metal, known as “shoes”, or through a focused laser beam aimed at the compaction point of the material into the substrate. Other options include, hot gas torches, infra red heaters and quartz lamps.

This unique method of consolidating thermoplastics utilizes a very short heating and cooling cycle at very high rates, where consolidation can occur at less than 0.5 seconds. This avoids material degradation issues, which are known to occur when thermoplastics are held at high temperatures for extended periods of time. The downside of this technology is that the short consolidation time leaves little time for diffusion of molecular chains to occur. This can lead to voids in the ply interfaces, resulting in reduced interlaminar shear strengths.

Related pages

| Page type | Links |

|---|---|

| Introduction to Composites Articles | |

| Foundational Knowledge Articles | |

| Foundational Knowledge Method Documents | |

| Foundational Knowledge Worked Examples | |

| Systems Knowledge Articles | |

| Systems Knowledge Method Documents | |

| Systems Knowledge Worked Examples | |

| Systems Catalogue Articles | |

| Systems Catalogue Objects – Material | |

| Systems Catalogue Objects – Shape | |

| Systems Catalogue Objects – Tooling and consumables | |

| Systems Catalogue Objects – Equipment | |

| Practice Documents | |

| Case Studies | |

| Perspectives Articles |

References

- ↑ 1.0 1.1 1.2 1.3 [Ref] Campbell, F.C. (2004). Manufacturing Processes for Advanced Composites. Elsevier. doi:10.1016/B978-1-85617-415-2.X5000-X. ISBN 9781856174152.CS1 maint: uses authors parameter (link) CS1 maint: date and year (link)

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.