Pultrusion of Thermoplastic Composites - A334

Introduction[edit | edit source]

Pultrusion is an automated composite manufacturing process allowing the continuous production of constant cross-section beams. Pultrusion has been successfully used in the industry with thermoset polymers. The pultrusion of thermoplastic polymer composites, however, has not reached the same level of industrial penetration. This is mostly due to the high viscosity of melted thermoplastic polymers that hinders impregnation as well as surface finish issues.

In this webinar, we discuss the scientific and technical challenges that were solved to mature this technology. Results are presented with a wide range of reinforcements such as flax, glass, carbon combined with polymers such as polypropylene, nylon, polyetherimide, and polyetheretherketone. An application of the process: pultrusion of beams with off-axis properties will be covered. The presentation finally discusses some applications of the technology and how to assess if it is suitable for your applications.

This presentation is part of CKN’s ongoing Application + Impact (AIM) webinar series. Content discussed in the webinar is linked to the Knowledge in Practice Centre, allowing users to access this and other content in a consistent and coherent manner.

Presenter[edit | edit source]

Prof. Louis Laberge Lebel

Associate Professor, Polytechnique Montreal

Director of the Advanced Composites and Fiber Structures Laboratory

Webinar[edit | edit source]

Webinar slides[edit | edit source]

Webinar slides available by clicking on the icon below

Additional information for select chapters[edit | edit source]

| Chapter | Chapter Title | Links to related information in the Knowledge in Practice Centre | |||

|---|---|---|---|---|---|

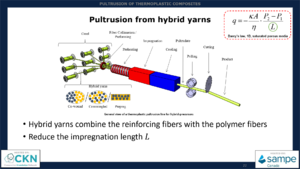

| 1 | Welcome & introductions | N/A | |||

| 2 | Knowledge in Practice Centre | ||||

| 3 | Overview | ||||

| 4 | Introduction to thermoset pultrusion | ||||

| 5 | Preforming station | N/A | |||

| 6 | Impregnation station | N/A | |||

| 7 | Pultrusion die | N/A | |||

| 8 | Cooling, pulling and cutting stations | N/A | |||

| 9 | Thermoplastic polymers overview | ||||

| 10 | Melt viscosity and flow of thermoplastics | ||||

| 11 | Deconsolidation of thermoplastics | ||||

| 12 | Bonding of TP polymers & effects on pultrusion | ||||

| 13 | Types of TP Pultrusion: Injection | N/A | |||

| 14 | Types of TP Pultrusion: Reaction injection | N/A | |||

| 15 | Types of TP Pultrusion: Hybrid yarns | N/A | |||

| 16 | Impregnation of fibres | ||||

| 17 | Technologies for success: Hybrid yarns | N/A | |||

| 18 | Technologies for success: Multi-die impregnation | N/A | |||

| 19 | Technologies for success: Vaccuum assisted impreg. | N/A | |||

| 20 | Technologies for success: Cooling technologies | 21 | Sloughing defects | N/A | |

| 22 | Thin wall cooling concept for defect mitigation | N/A | |||

| 23 | Examples and Applications | N/A | |||

| 24 | Cooling system validation: Deconsolidation effects | ||||

| 25 | Cooling system validation: Pulling forces | N/A | |||

| 26 | Other applications: Braid-trusion | N/A | |||

| 27 | Other applications: Thermoplastic composite rivets | N/A | |||

| 28 | Other applications: Overmoulding of pultrusions | N/A | |||

| 29 | Other applications: Long fibre TP pellets | N/A | |||

| 30 | Summary & wrap-up | N/A | |||

| 31 | Q&A | N/A |

Related pages

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.