Optimizing Cost vs Weight for Low Production Volume Parts - C112

| Optimizing Cost vs Weight for Low Production Volume Parts | |

|---|---|

| Case study | |

| |

| Document Type | Case study |

| Document Identifier | 112 |

| Themes | |

| Tags | |

Summary[edit | edit source]

Twenty-three vehicle body panels for an amusement park attraction were originally designed using carbon fibre materials. The client desired to reduce manufacturing costs. A project was launched to evaluate new manufacturing processes and materials to reduce cost. A significant cost reduction was achieved by switching materials, but a weight penalty was incurred by making the change.

Challenge[edit | edit source]

Safety is imperative for amusement park attractions. These parts needed to achieve minimum specified safety factors for over 20 load cases. This included static load cases to ensure the components could survive maximum expected loads, fatigue load cases to ensure the components could last for the design life of the attraction, and impact load cases from guests stepping on or kicking the parts.

The parts also needed to satisfy maximum weight requirements. This was critical because as the weight of the body panels increase, the weight of the supporting sub-structures must also increase. For example, as the body panels become heavier the size of the chassis, propulsion system, and ride support structures must all increase.

Only ten assemblies were required, which presented another challenge when selecting manufacturing methods. Wet bagged processing of carbon fibre was initially selected to meet these requirements. However, the initial cost estimates exceeded the available budget. A new material process needed to be identified that could meet the safety requirements, but at a cheaper cost while minimizing the increase in weight.

Approach[edit | edit source]

At the start of the project a number of materials and manufacturing processes were considered for use in these components. They included:

- E-glass using hand layup processing. This option would have been the least expensive option, but the achievable fibre content (and associated strength) would have been too low to meet the safety factor requirements.

- Carbon fibre using hand layup processing. This option would have increased material costs compared to E-glass, but kept the labour costs similar to option 1. However, initial analysis showed that the fibre content was too low to meet the safety factor requirements.

- E-glass using wet bag processing. This option increased the fibre content and strength of the parts. It increased production costs due to labour and materials required for bagging, but kept tooling costs relatively low.

- Carbon fibre using wet bag processing. This option increased the fibre content and strength of the parts. It increased production costs due to labour and materials required for bagging, and had more expensive material costs than option 3, but kept tooling costs relatively low.

- Carbon fibre prepreg processed in an oven. This option would have resulted in higher strength values and lower weight, but the materials were deemed too expensive.

- Carbon fibre prepreg processed in an autoclave. This option was eliminated due to the high material costs and because the production volumes were low, the tooling costs would have been too high.

Based on the information above, wet bagged E-glass and wet bagged carbon fibre were selected for further investigation. This kept tooling costs low, while resulting in fibre contents that were high enough to meet the load requirements of the attraction.

Minimum static and fatigue safety factors were defined for each material. These were calculated based on a number of factors including the type of manufacturing process, the material form (unidirectional, woven, etc.), whether the material was post cured, and the fatigue S-N curve. The required static safety factor was identical for the carbon fibre and E-glass materials. Since the carbon fibre had a higher strength than the E-glass, it was able to achieve this safety factor using less material and this resulted in lighter parts. For more information on considerations for choosing safety factors look at [[A366| Safety Factors. For a discussion on fatigure failure and fatigue limits in composite materials, read Fatigue Limits.

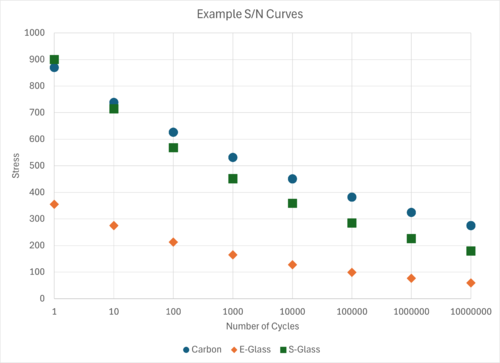

The required fatigue safety factor was much higher for the E-glass since fibreglass typically has a shorter fatigue life than carbon fibre. For an example of a typical strength-life (S-N) curves for these materials, see Fig. 1. It is obvious from the chart that carbon fibre has a higher static strength than E-glass, but equally important is the slope of the curve. The slope of the curve is steeper for E-glass than for carbon fibre. This means that for E-glass to reach ten million cycles, the stress must be less than 17% of its original strength. For carbon fibre to reach ten million cycles, the stress must be less than 32% of its original strength.

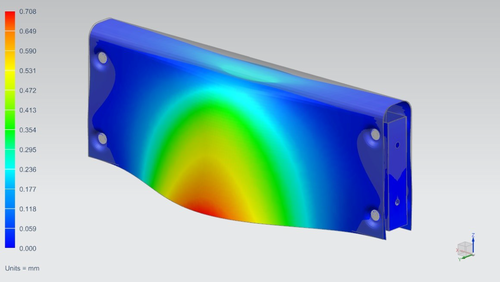

Next, a finite element model of the assembly was created using NX software that included all 23 body panels and their support structures. Mechanical properties were specified for both material systems, then initial ply layups that defined material thickness and orientation were defined. Each of the static, fatigue, and impact load cases were created along with the applicable constraints. After the analysis was run, the deflection and stress results were reviewed to determine if each component met the safety factor requirements. An example of deflection results is shown in Fig. 2 for an impact load case that considered the force of a guest stepping on the component. For those parts that were below the required safety factor or deflection was too high, the number and/or orientation of the plies were adjusted to meet the safety factors. For those parts that greatly exceed the required safety factors, the number of plies were reduced to minimize weight. After the changes were made the analysis was run again.

The final results showed that the weight of the E-glass design was 35% greater than the carbon fibre design. The client decided to proceed with the carbon fibre design to minimize weight. Production drawings were created and sent for quotation. When the manufacturing quotations were received it was discovered that the price to build the components was higher than budgeted due to the low production volumes. Although the E-glass version would have been less expensive to manufacture, the weight was too high to meet the requirements. Specifically, the weights of the E-glass components were high because of its relatively poor fatigue performance.

A new assessment of potential material and manufacturing processes was launched. The two main/common classes of glass fibre are E-glass and S-glass. E-glass is much more common and less expensive. S-glass has superior static and fatigue strength as shown in S/N curve in Fig. 1, but is much higher in price. Due to its higher strength, S-glass was selected for further investigation. Reviewing the S/N curve in Fig. 1 showed that the slope of the curve was less for S-glass compared to E-glass. For S-glass to reach ten million cycles, the stress must be less than 20% of its original strength. This meant the required fatigue safety factor for S-glass was lower than for E-glass, although it was still higher than for carbon fibre. The finite element model was updated with the new material properties and rerun. After reviewing the initial results, the number of plies and their orientation were optimized for the new grade of fibreglass to minimize weight while ensuring the components still met the required safety factors .

Outcome[edit | edit source]

The results of the analysis ensured the attraction remained compliant with all safety standards and regulations. The initial results showed that the E-glass design was approximately 35% heavier than the carbon fibre design. The next analysis showed that the switch from carbon fibre to S-glass increased the weight of the components by 15.4%.

For the initial carbon fibre design the cost of tooling made up approximately 40% of the total manufacturing costs, while the remaining 60% was the cost to manufacture the components. Since both the carbon fibre and S-glass designs used the same processing method the tooling costs were approximately equal. However, the component costs decreased by a factor of 2.5 when switching to S-glass from carbon fibre. Further cost reductions were possible if E-glass had been adopted, but it was found that the fatigue performance of E-glass was too low and would have resulted in the components exceeding the weight limits for this application.

Return to Case Studies

Related pages[edit | edit source]

- Material Selection

- Composite materials engineering webinar session 2 - Constituent Materials - Fiber

- Composite materials engineering webinar session 10 - Failure of composites

Related pages

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.