Costing composite parts - A246

| Costing composite parts | |

|---|---|

| Perspectives article | |

| |

| Document Type | Article |

| Document Identifier | 246 |

| Tags | |

|

Webinar Date

| |

Introduction[edit | edit source]

Accurately estimating the cost of manufacturing a composite part is essential to the success of small, medium and large businesses alike; but where should you begin? Many factors such as material and consumable prices, labour cost, purchase and maintenance of equipment and tooling, energy cost, development cost, overhead cost as well as production run numbers and rates can affect the total cost of a part. Many of these factors also involve a certain amount of uncertainty.

In this virtual application + impact mobilization (AIM) event we outline the key aspects of costing composite parts and draw your attention to aspects of costing that perhaps you haven’t considered before.

Webinar[edit | edit source]

*Note: Content between 51:46 and 1:04:09 has been re-recorded after the live webinar to clarify aspects of the example

Webinar slides[edit | edit source]

Webinar slides available by clicking on the icon below

Additional information for select chapters[edit | edit source]

| Chapter | Chapter Title | Links to related information in the Knowledge in Practice Centre |

|---|---|---|

| 1 | Welcome & introductions | N/A |

| 2 | Outline and learning objectives | N/A |

| 3 | Cost commitment throughout a development project | N/A |

| 4 | Material cost | Future content |

| 5 | Carbon fibre cost breakdown | N/A |

| 6 | Carbon fibre market share | N/A |

| 7 | Resin cost | Future content |

| 8 | Manufacturing cost comparison with steel | N/A |

| 9 | Composites supply chain | N/A |

| 10 | Making composites cost competitive | N/A |

| 11 | Case study: BMW & composites | N/A |

| 12 | Composites cost modelling options | Future content |

| 13 | Cost modelling - Top-down estimation | Future content |

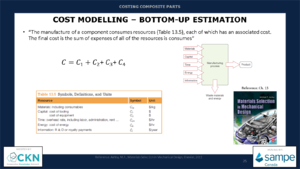

| 14 | Cost modelling - Bottom-up estimation | Future content |

| 15 | Example: Composite wheel cost estimating | N/A |

| 16 | Example case 1: Pre-preg process | N/A |

| 17 | Example case 2: RTM process | N/A |

| 18 | Wrap-up | N/A |

| 19 | Q&A | N/A |

Related pages

| Page type | Links |

|---|---|

| Introduction to Composites Articles | |

| Foundational Knowledge Articles | |

| Foundational Knowledge Method Documents | |

| Foundational Knowledge Worked Examples | |

| Systems Knowledge Articles | |

| Systems Knowledge Method Documents | |

| Systems Knowledge Worked Examples | |

| Systems Catalogue Articles | |

| Systems Catalogue Objects – Material | |

| Systems Catalogue Objects – Shape | |

| Systems Catalogue Objects – Tooling and consumables | |

| Systems Catalogue Objects – Equipment | |

| Practice Documents | |

| Case Studies | |

| Perspectives Articles |

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.