Composite materials engineering webinar session 4 - Thermal management and resin cure - A123

| Composite materials engineering webinar session 4 - Thermal management and resin cure | |

|---|---|

| Perspectives article | |

| |

| Document Type | Article |

| Document Identifier | 123 |

| Themes | |

| Tags | |

|

Webinar Date

| |

Introduction[edit | edit source]

Thermal management involves heat transfer into and out of the composite material during the curing/forming process. In this session we look at factors affecting heat transfer, how to control them, and how to simulate the thermal management of a process.

Webinar[edit | edit source]

Webinar slides[edit | edit source]

Webinar slides available by clicking on the icon below

Additional information for select chapters[edit | edit source]

| Chapter | Chapter Title | Links to related information in the Knowledge in Practice Centre |

|---|---|---|

| 1 | Welcome & introductions | N/A |

| 2 | Overview of Webinar Series | |

| 3 | Introduction to thermal management | |

| 4 | Introduction to thermo-chemical reaction (curing) | |

| 5 | Flow & compaction phenomena affected by cure | Future content |

| 6 | Residual stress and dimensional changes | Future content |

| 7 | Tool-part interaction | Future content |

| 8 | How curing is affected by part thickness | Future content |

| 9 | Convective curing with autoclaves | |

| 10 | Common airflow within an autoclave or oven | |

| 11 | Airflow around a common tooling geometry | |

| 12 | Effect of tool sub-structure on heat transfer | |

| 13 | Fundamentals of convective heat transfer & HTC's | |

| 14 | Thermal mass and specific heat capacity | |

| 15 | Loading (tool positioning) autoclaves and ovens | Future content |

| 16 | Tooling materials | |

| 17 | Comparison of tooling materials | |

| 18 | Unintended consequences of changing tool material | Future content |

| 19 | Comparison of tools made from different materials | |

| 20 | 1D thermo-chemical analysis: Introduction | Future content |

| 21 | 1D thermo-chemical analysis: Energy balance | Future content |

| 22 | 1D thermo-chemical analysis: Heat up step | Future content |

| 23 | 1D thermo-chemical analysis: Polymerization step | Future content |

| 24 | Simulation tools for thermal management | Future content |

| 25 | Simplifying complex thermo-chemical analysis to 1D | Future content |

| 26 | 1D system definition for autoclaves & ovens | Future content |

| 27 | 1D system definition for closed heated moulds | Future content |

| 28 | 1D system definition for open heated moulds | Future content |

| 29 | 1D system definition for closed mould ambient cure | Future content |

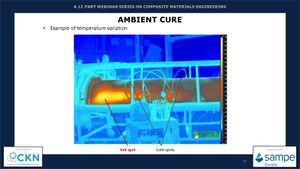

| 30 | Infrared measurement of temperature during cure | Future content |

| 31 | Example of typical MRCC (thermal cure cycle) | Future content |

| 32 | Thermal cure cycle vs cure specification | Future content |

| 33 | Example: acceptable cure cycle | Future content |

| 34 | Case study: ATCAS program sandwich panel | N/A |

| 35 | Case study: ATCAS program non-accepted cure cycles | N/A |

| 36 | Case study: ATCAS program accepted cure cycle | N/A |

| 37 | Wrap-up | N/A |

| 38 | Q&A | N/A |

Related pages

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.