Polymer properties - A212

| Polymer properties | |

|---|---|

| Foundational knowledge article | |

| |

| Document Type | Article |

| Document Identifier | 212 |

| Themes | |

| Tags | |

Overview[edit | edit source]

This page provides links to polymer properties. In the Knowledge in Practice Centre (KPC), polymer properties are defined as properties that are unique attributes to polymer materials.

Below are polymer property pages found in the KPC:

Chemical Properties[edit | edit source]

Degree of Cure[edit | edit source]

For thermoset polymer resins (e.g. epoxies, polyesters), the degree of cure (DOC), \(x\), is a numerical representation of how far the chemical curing reaction (crosslinking process) has advanced. It is considered a processing state variable used to describe the current polymer material state based on its process cure history.

The degree of cure (DOC) is usually not directly measured. However, the curing reaction for thermoset polymers is exothermic in nature and generates heat. This allows the DOC to be measured through differential scanning calorimetry (DSC) characterization of resin samples and is modelled as follows\[x=1-\frac{H_{res}}{H_R}=1-\frac{\int_{t1}^{t\infty} hdt}{\int_{0}^{t\infty} hdt}=\frac{\int_{t0}^{t1} hdt}{\int_{0}^{t\infty} hdt}=\frac{\int_{t0}^{t1} hdt}{H_R}\]

Where,

\(x=\) Degree of cure

\(H_R=\) Heat of reaction - total [J/g]

\(H_{res}=\) Heat of reaction - residual [J/g]

\(h=\) Specific heat flow [W/g]

Click here to learn more about degree of cure.

Heat of reaction[edit | edit source]

The polymerization process for thermoset resins is an exothermic reaction generating heat. Measured in energy/mass, the total heat of reaction represents this thermal energy released by a thermoset polymer during its curing process.

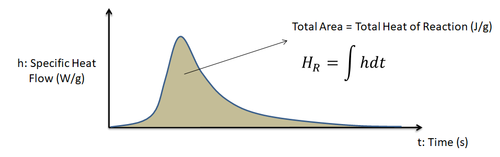

As illustrated below, the total heat of reaction of the resin system is the area under a differential scanning calorimetry (DSC) obtained heat flow curve.

Click here to learn more about heat of reaction.

Chemical properties coming soon[edit | edit source]

- Degree of crystallization (content coming soon)

Physical Properties[edit | edit source]

Melting temperature[edit | edit source]

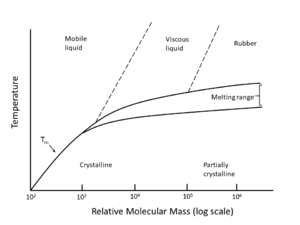

Melting temperature (Tm) – The temperature point at which the polymer physically transitions from a solid to viscous flow upon heating, or vice versa – from melt to a solid upon cooling.

The phase transition of melting is a characteristic exhibited by thermoplastics. For thermosets, melt and subsequent flow is not physically possible due to their fundamental molecular crosslink structure.

Heated beyond the melting temperature (Tm), the polymer transitions from a solid to a viscous liquid like behaviour that can flow. At this phase change, a polymer experiences a large change in specific volume and the polymer chains gain mobility. In reverse, the process of cooling from above Tm dropping below it to solidify, is referred to as crystallization.

Click here to learn more about thermal phase transitions of polymers.

Glass transition temperature[edit | edit source]

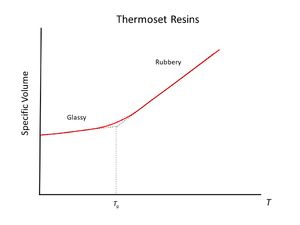

Glass transition temperature (Tg) – The temperature region where the polymer behaviour transitions from a hard-glassy material, to that of a soft rubbery material. A sudden loss in mechanical stiffness occurs.

Polymers are classified as glassy when their molecular backbones exhibit the inability to move and remain “frozen” in crumpled immobile conformations. Below Tg, upon heating only thermally induced expansion between the molecules occurs. Above Tg, amorphous regions within the polymer observe liquid-like “flow” with the molecular chains gaining rapid ability to move freely, while crystalline regions remain locked in the glassy state configuration.

As an outcome of this behavioral transition, a polymer exhibits a sudden change in the response of specific volume to change in temperature (thermal expansion) at the Tg point. Mechanically, a softening drop in mechanical stiffness occurs. This substantial drop in mechanical stiffness is shown in the following image, showing a polymer below and above its glass transition temperature.

Click here to learn more about thermal phase transitions of polymers.

Mechanical Properties[edit | edit source]

Viscosity (resin viscosity)[edit | edit source]

The viscosity (\(\mu\)) of a fluid represents its resistance to deformation at a given rate, and in simplest form is\[\mu = \frac{\tau}{\dot{\gamma}}\]

Where,

\(\tau = \) Shear stress

\(\dot{\gamma} = \) Shear rate

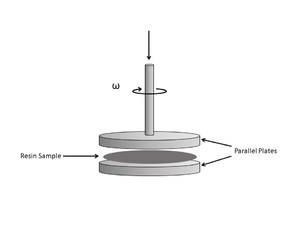

Resin viscosity is typically measured using a rheometer with parallel plate geometry, and disposable aluminum plates are used since the material cures to the plates. Whereas the viscosity of a thermoplastic drops exponentially but monotonically with increasing temperature, thermoset resins behave in a more complex fashion. Initially, viscosity drops in the same manner as a thermoplastic, but once cure kicks off, the increasingly higher molecular weight and crosslinked polymer structure

In composites processing, viscosity is an indicator of how easily the resin matrix will mix with the reinforcement and how well it will stay in place during processing. The lower the viscosity, the more easily resin flows. Resin viscosity is an important composite processing consideration for resin infusion processes where the dry fibre preform is fully infused with flowing resin, and likewise for prepreg processing – despite the much shorter length scale of resin flow – to ensure full resin wet-out of the reinforcement fibres.

Resin viscosity ranges considerably across different resin chemistries and formulations. Additionally, resin viscosity is directly influenced by the following factors:

- Temperature (increase temperature = viscosity decrease)

- Degree of cure – thermoset polymers (increase DOC = viscosity increase)

- Resin fillers and tougheners (increase particulate content = viscosity increase)

Thermal management of viscosity[edit | edit source]

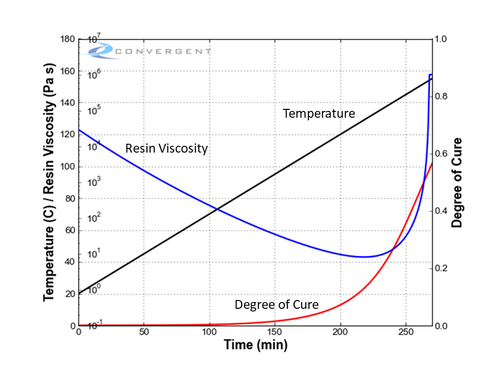

Two of the above listed viscosity influencing factors can be controlled during processing through thermal management – control of temperature. The effects of temperature and its downstream linked degree of cure (DOC) are illustrated below for a thermoset resin system.

Resin viscosity drops as a function of increasing temperature. Countering this resin viscosity drop, the thermoset crosslinking reaction takes place with elevated temperature and sees increasing molecular weight and restriction in mobility of the polymer – resulting in a corresponding increase in resin viscosity as the thermosetting reaction progresses. During a heated cure cycle, the resin therefore experiences the following sequence:

- An initial lowering of resin viscosity as the resin is being heated, this is quickly countered and overtaken with,

- An increasing resin viscosity due to the thermoset reaction effects.

- Resin viscosity will continue to increase until the resin reaches the gelation point, where it takes on the behaviour of a semi-solid.

These two competing factors (temperature, and DOC – resin reaction) affecting resin viscosity must be balanced for setting the resin’s processing window. This is of particular importance in resin infusion process steps, where liquid resin must fully infuse the fibre preform – sometimes with flow lengths in the range of meters. Increasing temperature lowers the resin viscosity which aids in resin/fibre wetout. This is the fundamental motive behind the practice of performing heated resin infusion. However, in doing so, there is also an associated risk that the elevated temperature kicks off and accelerates the resin reaction. This can quickly become the dominating effect by rapidly and irreversibly increasing the resin viscosity. If the resin’s degree of cure progresses too quickly, this will quickly inhibit the resin’s ability to flow and ultimately reduce the time available for the resin to flow. Insufficient resin infusion may occur, and result in dry spots with a partially resin infused fibre preform.

KPC page for viscosity (resin viscosity) coming soon.

Mechanical properties coming soon[edit | edit source]

- Viscoelasticity (content coming soon)

- Yield and fracture (content coming soon)

Property Measurement[edit | edit source]

For methods to obtain material property values, please see the Foundational Methods Documents page.

Link to Foundational Method Documents page

Other Material Properties[edit | edit source]

Explore this area further

Related pages

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.