Tensile Testing - M117

| Tensile Testing | |

|---|---|

| Foundational knowledge method | |

| |

| Document Type | Method |

| Document Identifier | 117 |

| Relevant Class |

Material |

| Tags | |

Introduction[edit | edit source]

This test is designed to find the in-plane properties of fibrous composites that have a balanced and symmetric layup with regards to the test direction. This page is based on the testing standard ASTM D3039: “Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials”[1] The test procedure uses a thin rectangular strip of composite material with a constant cross section (specimen), which is loaded into a test frame by grips clamping each end of the specimen. The load frame applies a constant strain in tension and records the force. This can then be used to determine the ultimate strength of the material. A strain gage may also be attached to the sample to determine the stress-strain response, to then find the elastic modulus, Poisson’s ratio, ultimate tensile strain and transition strain.

Below is an example of a tensile test being performed on unidirectional carbon specimen as seen in the webinar on Parameters for Structural Analysis of Composites.

For more information on test methods, see the following webinar: Composite materials engineering webinar session 12 - Testing

Test Specimen[edit | edit source]

For tensile testing of homogenous materials, the test specimens are machined into a "dog bone" shape, where the top and bottom are wider. This is to concentrate the forces away from the grips into the region where gages are attached. This is, however, not feasible for unidirectional composites as axial splitting will occur along the fibers causing the sample to prematurely fail[2]. To avoid this, composite tensile testing specimens need to be rectangular with an even cross section and/or have tabs bonded to the ends, see section on tabs below. For more on challenges with the composite tensile test, see CompositesWorld: Tensile Testing of Composites

The geometry of the specimens can be varied depending on the material being tested. There are very few mandatory requirements for the geometry, but there are some non-mandatory suggestions for dimensions. Below are two tables of the mandatory and suggested dimensional requirements[1].

| Parameter | Requirement |

|---|---|

| Shape | Constant rectangular cross section |

| Minimum Length | Grip area + 2 x width + gage length |

| Width | As needed ±1 % of width |

| Thickness | As needed ±4 % of thickness |

| Flatness | Flat with light finger pressure |

When determining the dimensions of a test specimen the purpose is to have the failure occur in the gage section of the specimen. There should also be a representative number of fibers in the cross section of the bulk material. The length of the specimen must be longer than the minimum set in table, but it is recommended to aim for significantly longer as this will minimize bending stresses if the grips are slightly misaligned or there is torsion in the specimen. The gages should be placed centrally away from the grips. The table below is a conglomeration of a number of test labs and their best practice that have yielded reliable results[1].

| Parameter | 0° Unidirectional | 90° Unidirectional | Discontinuous or Balanced Layup |

|---|---|---|---|

| Width (mm) | 15 | 25 | 25 |

| Length (mm) | 250 | 175 | 250 |

| Thickness (mm) | 1 | 2 | 2.5 |

| Tab Length (mm) | 56 | 25 | Emery cloth |

| Tab Thickness (mm) | 1.5 | 1.5 | - |

| Tab bevel Angle (°) | 7 - 90 | 90 | - |

Tabs[edit | edit source]

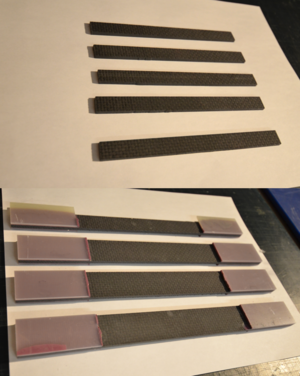

There are many different methods of clamping the test specimens to the load fixture and one of the options is to bond tabs onto the ends of the specimen. Tabs are usually made from E-glass and are used to transfer loads into the specimen and prevent premature failure. The tabs also prevent the specimen from being damaged by the grips as they are tightened.

The tab geometry and its success is dependent on the specimen material and fiber orientation, as well as the types of grips used in the test. For example, the bevel angle has an effect on the success of the test with different grips. Pressure-operated non-wedge grips show higher success with 90° edges, whilst wedge operated grips show success with low angle edges, 7 to 10°[1]. It is important that the tab thickness is kept the same on both sides so that the specimen is positioned in the center of the grips.

To bond tabs onto the specimen it is recommended to use a high-elongation adhesive. The adhesive should have a minimal thickness and a uniform bond line.

Procedure[edit | edit source]

Firstly, measure the specimen cross sectional area, measure both the width and thickness in three areas and take the average. Secondly, ensure the load frame is calibrated.

The test is to be performed as a constant strain procedure, where the test is to be performed in a time window of 1 to 10 minutes. For a test setup with the ability to apply a constant strain, the rate should be 0.01 min-1. If this is not possible, then a constant crosshead speed of the load frame is recommended to be set to 2 mm/min[1]. When loading the sample into the grips it is important that the specimen is aligned precisely with the grips and not loaded at an angle. Misalignment will drastically alter the outcome of the results as the material strength rapidly changes due to its anisotropic nature[3].

To validate the experiment, ensure that the failure has not occurred in the region of the grips or at any obvious flaw in the sample. It may be necessary to alter the way the specimen is gripped due to that all loads being transferred into the sample is done through the friction between the grips and the specimen. The tensile loading of the sample is presented though the shear force from the grip and specimen interface, which is equal to the clamping force times the coefficient of friction. It is not recommended to alter the surface of the specimen as it may damage it, but instead alter the surface of the grips to provide more friction or place emery cloth between the clamps and the specimen. It has also been suggested that the surface of the clamps may be coated in rubber or tungsten carbide spray in order to increase friction as well[4]. Five repeat tests are generally recommended to get somewhat statistically significant results.

Calculations[edit | edit source]

Below are the calculations that can be performed with the test results to find the material properties of the laminate.

To read more about how to predict the material properties of laminae and laminates see Micro-Mechanics and Macro-Mechanics.

Ultimate Tensile Strength[edit | edit source]

\[F^{\mathrm{tu}}=\frac {P^{\max } }{ A}\] \(F^{\mathrm{tu}}\) = Ultimate tensile strength (MPa)

\(P^{\max}\) = Maximum force before failure (N)

\(A\) = Average cross sectional area (\(mm^2\))

Tensile Strain[edit | edit source]

\[\varepsilon_i=\frac {\delta_i }{ L_g}\] \(\varepsilon_i\) = Tensile strain at \(i_{th}\) data point

\(\delta_i\) = Extensometer displacement at \(i_{th}\) data point

\(L_g\) = Extensometer gage length (mm)

Elastic Modulus[edit | edit source]

\[E=\frac{\Delta \sigma}{\Delta \varepsilon}\] \(E\) = Tensile modulus of elasticity (GPa)

\(\Delta \sigma\) = Differnece in applied tensile stress between two strain points (MPa)

\(\Delta \varepsilon\) = Difference between two strain points

Poisson's Ratio[edit | edit source]

\[v=-\frac{\Delta \varepsilon_t }{ \Delta \varepsilon_l}\] \(v\) = Poisson's ratio

\(\Delta \varepsilon_t\) = Difference in lateral strain between the two longitudinal strain points

\(\Delta \varepsilon_l\) = Difference between the two longitudinal strain points

Related pages

| Page type | Links |

|---|---|

| Introduction to Composites Articles | |

| Foundational Knowledge Articles | |

| Foundational Knowledge Method Documents | |

| Foundational Knowledge Worked Examples | |

| Systems Knowledge Articles | |

| Systems Knowledge Method Documents | |

| Systems Knowledge Worked Examples | |

| Systems Catalogue Articles | |

| Systems Catalogue Objects – Material | |

| Systems Catalogue Objects – Shape | |

| Systems Catalogue Objects – Tooling and consumables | |

| Systems Catalogue Objects – Equipment | |

| Practice Documents | |

| Case Studies | |

| Perspectives Articles |

|

References

- ↑ 1.0 1.1 1.2 1.3 1.4 [Ref] ASTM International (1997). ASTM D3039: Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials (Report).

This test method determines the in-plane tensile properties of polymer matrix composite materials reinforced by high-modulus fibers. The composite material forms are limited to continuous fiber or discontinuous fiber-reinforced composites in which the laminate is balanced and symmetric with respect to the test direction.

line feed character in|quote=at position 112 (help)CS1 maint: uses authors parameter (link) - ↑ [Ref] Adams, Daniel (2015). "Tensile testing composites: Simple concept, difficult in practice" (published 1 June 2015). Retrieved 14 October 2022.CS1 maint: uses authors parameter (link) CS1 maint: date and year (link)

- ↑ [Ref] Saba, N. et al. (2019). "An overview of mechanical and physical testing of composite materials". Woodhead Publishing. doi:10.1016/B978-0-08-102292-4.00001-1. ISBN 9780081022924. Cite journal requires

|journal=(help);|access-date=requires|url=(help)CS1 maint: extra punctuation (link) CS1 maint: uses authors parameter (link) - ↑ [Ref] Carlsson, Leif A et al. (2014). Experimental Characterization of Advanced Composite Materials. CRC Press (published March 2014). doi:10.1201/b16618. ISBN 9780429109393.CS1 maint: extra punctuation (link) CS1 maint: uses authors parameter (link) CS1 maint: date and year (link)

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.