Developing production scale tooling - P129

| Developing production scale tooling | |||||||

|---|---|---|---|---|---|---|---|

| Practice document | |||||||

| |||||||

| Document Type | Practice | ||||||

| Document Identifier | 129 | ||||||

| Themes | |||||||

| Tags | |||||||

| Objective functions |

| ||||||

| MSTE workflow | Development | ||||||

| Prerequisites | |||||||

"Q: As part of my development strategy, I am considering transitioning from temporary development tooling to more durable production steel tooling with the exact same shape and bagging. Can I still cure good quality parts, with the same cure program in the same cure vessel?"

A: Depending on how big the change from temporary to production tooling is, you will likely have to alter your cure cycle. Production tooling is often more thermally massive, meaning it will take longer to heat up and will induce a larger thermal lag between the air and tool and the air and the part (for a convective heating system). In order to compensate for this, a slower ramp rate or longer hold times may have to be introduced. The benefit of a more thermally massive tool is that it will assist in absorbing the exothermic heat generated during cure.

Overview[edit | edit source]

Changing to more durable tooling for production (often referred to as "hard tooling") will allow for more use out of the tool before it has to be retired. This is beneficial for high production volumes, where the tooling must withstand thousands of cure cycles. Steel and steel-nickel alloys, such as invar, are common materials used for high volume production tooling [1][2]. The downside to using such tooling materials is that they are heavy and expensive. Moreover, a change in tooling material also means a change in the system parameters. In particular, the thermal properties of the tool will have likely changed. Some potential major changes to consider are the thermal mass (as mentioned), thermal diffusivity, and the coefficient of thermal expansion (CTE). Changing the thermal properties of the tool can have a significant impact on the final quality of the part.

Thermal management considerations[edit | edit source]

Transitioning from soft to hard tooling will come with an increase in thermal mass of the tool. As a result, the tool will take longer to heat up and thermal lag will increase. However, the increase in thermal mass will also help absorb the exothermic heat generated, reducing the chance of thermally degrading the part during high temperature processing. The other thing to consider is the thermal diffusivity of the tool. If transitioning to metallic tooling for production, it is likely that the thermal diffusivity is relatively good. However, even among metals, thermal diffusivity may vary, with aluminum presenting a high diffusivity. An increased thermal diffusivity allows for more uniform temperature distribution across the tool surface. This is important for preventing hot and cold spots, allowing for a more even temperature distribution across the part as well. Moreover, improving thermal diffusivity allows for better conduction of heat through the tool, thus improving the efficiency at which the tool may draw heat away from the part during exotherm. To see a practical example of how a change in tooling material affects the thermal response of the tool, visit the following page.

The energy required to heat the tooling is determined by its thermal mass, as governed by the following equation:

\(Q=mC_p\Delta{T}\)Energy required to raise an object's temperature, where \(Q\) = energy, \(m\) = object mass, \(C_p\) = specific heat capacity, \(\Delta{T}\) = change in temperature from applied energy. Note that \(mC_p\) is the thermal mass of the object.

Thermal diffusivity can be calculated using the following equation:

\(\alpha=\frac{k}{\rho C_p}\)Thermal diffusivity, where \(\alpha\) = thermal diffusivity, \(k\) = thermal conductivity, \(\rho\) = density, and \(C_p\) = specific heat capacity.

The tables below provide a quantitative and qualitative list of typical thermal properties for tooling materials. Properties for composite tools are dependent on the fibre volume fraction and orientation. Note that in the second table, high and low thermal mass are shaded both red and green. The reason for this is that either can be beneficial or detrimental. A high thermal mass increases thermal lag and heat up time, but it decreases part exotherm. A low thermal mass decreases thermal lag and heats up quickly, but increases part exotherm.

| Tooling material | Density (kg/m3) | Specific heat capacity (J/kg-K) | Thermal conductivity (W/m-K) | Coefficient of thermal expansion - CTE (x10-6/°C) | Thermal diffusivity (x10-6m2/s) |

|---|---|---|---|---|---|

| Invar | 8000 | 515 | 11.0 | 0.6-1.5 | 2.67 |

| Mild steel | 7850 | 510 | 55 | 11 | 13.7 |

| Carbon-epoxy composite | 1580 | 870 | 0.7 (through-thickness) | -0.5 (in-plane) 22.5 (through-thickness) |

0.5 (through-thickness) |

| Aluminum | 2710 | 896 | 167 | 23 | 68.9 |

| Tooling material | Cost | Durability | Weight | Thermal mass | Thermal conductivity | Coefficient of thermal expansion (CTE) | Thermal diffusivity |

|---|---|---|---|---|---|---|---|

| Invar | $$$ | Excellent | Heavy | High | Moderate | Low | Low |

| Steels | $$$ | Excellent | Heavy | High | Good | Moderate | Moderate |

| Composites | $ | Low | Light | Low | Low | Moderate | Low |

| Aluminum | $$ | Good | Moderate | Low | Excellent | High | High |

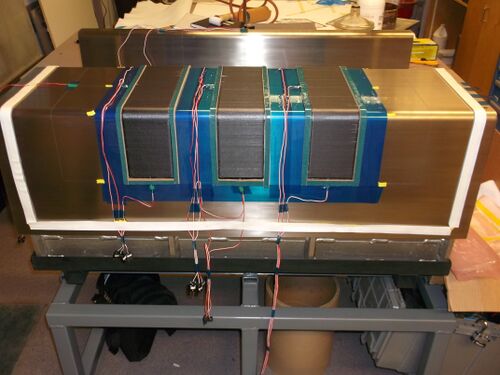

Verifying that the tool operates as expected is critical for evaluating the performance of the tool. Attaching thermocouples to the surface and under structure of the tool when performing the initial runs will ensure a better understanding of the heat transfer occurring in the tool during production. See image below for an example.

The other aspect to consider when changing tooling is how it may influence airflow in a convective heating system. However, in this case, if the shape of the tool is not being changed, then the airflow around the tool should remain the same. In order to ensure that airflow, and therefore the heat transfer coefficient (HTC), has not changed, the tool-part assembly should be placed in the same location in the equipment during production as it was during qualification.

To learn more about how tooling choices may affect the thermal response of the part, visit effect of tooling in a thermal management system.

Materials deposition and consolidation management considerations[edit | edit source]

Link to Materials deposition and consolidation management (MDCM)

Tooling may influence the flow characteristics of the material by altering the thermal profile of the part. This, in turn, may alter the material's viscosity evolution. To learn about ensuring appropriate resin flow, visit the following page: ensuring appropriate resin flow and part consolidation for a new material.

Residual stress and dimensional control management considerations[edit | edit source]

Link to residual stress and dimensional control management

The coefficient of thermal expansion (CTE) is an important factor that should be considered when changing tooling material. If the mismatch in CTE between the tool and part is considerable, and this is not mitigated for, then the part may deform during cure or upon demoulding. The best way to mitigate for this is to match the tool CTE with the part CTE. Generally speaking, composite materials have a low CTE while metallic tools have a much higher CTE. The exception is invar, which has a very low CTE and is therefore a preferable option for advanced tooling choices. However invar is also very expensive, heavy, and thermally massive. Composite tools, may also offer a close match in CTE to composite parts. However, because the resin and fibres of a composite material exhibit different CTEs, the overall CTE for a composite part is dependent on the fibre volume fraction and orientation of the fibres. Therefore, it can't be assumed that all composite parts, even if made with the same materials, have the same CTE. The same is true for composite tooling.

Another way to mitigate CTE-induced deformation at the tool-part interface is to include a low-friction film between the two surfaces. This may be a release agent, release film, teflon film, or other consumable.

General CTE values for common tooling materials are provided in the table below:

| Material | CTE (x10-6/°C) |

|---|---|

| Aluminum | 23 |

| Steel | 11 |

| Invar | 0.6 to 1.5 |

| Epoxy | 45 to 62 |

| Polyester | 60 to 200 |

| Vinylester | 100 to 150 |

| Carbon fibre (longitudinal) |

-0.2 to -0.5 |

| Carbon fibre (transverse) | 10 to 15 |

| E-glass fibre (longitudinal) | 5 |

| E-glass fibre (transverse) | 5 |

Related pages

| Page type | Links |

|---|---|

| Introduction to Composites Articles | |

| Foundational Knowledge Articles | |

| Foundational Knowledge Method Documents | |

| Foundational Knowledge Worked Examples | |

| Systems Knowledge Articles | |

| Systems Knowledge Method Documents | |

| Systems Knowledge Worked Examples | |

| Systems Catalogue Articles | |

| Systems Catalogue Objects – Material | |

| Systems Catalogue Objects – Shape | |

| Systems Catalogue Objects – Tooling and consumables | |

| Systems Catalogue Objects – Equipment | |

| Practice Documents |

|

| Case Studies | |

| Perspectives Articles |

References

- ↑ [Ref] CompositesWorld (2016). "Materials & Processes: Tooling for composites". Retrieved 19 April 2021.CS1 maint: uses authors parameter (link) CS1 maint: date and year (link)

- ↑ [Ref] CompositesWorld (2007). "Tooling considerations". Retrieved 19 April 2021.CS1 maint: uses authors parameter (link) CS1 maint: date and year (link)

- ↑ [Ref] Daniel, Isaac M.; Ishai, Ori (2006). Engineering Mechanics of Composite Materials. Oxford University Press. ISBN 978-0-19-515097-1.CS1 maint: uses authors parameter (link) CS1 maint: date and year (link)

- ↑ [Ref] MatWeb LLC. "MatWeb: Online Materials Information Resource". Retrieved 9 September 2020.CS1 maint: uses authors parameter (link)

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.