Automotive Battery Enclosure Material and Manufacturing Assessment - C117

| Automotive Battery Enclosure Material and Manufacturing Assessment | |||||||

|---|---|---|---|---|---|---|---|

| Case study | |||||||

| |||||||

| Document Type | Case study | ||||||

| Document Identifier | 117 | ||||||

| Objective functions |

| ||||||

| MSTE workflow | Development | ||||||

| Prerequisites | |||||||

Summary[edit | edit source]

A lightweight and cost-effective enclosure to house the batteries for an electric vehicle was required. Initially, an assessment was made between metallic and composite designs in which the composite design was selected (for more on when to use composites, see When to Use Composites - A360). An infusion manufacturing process was selected based on the initial production volumes and a detailed design was created and verified. As production volumes increased, an assessment of the required design changes and capital investments for high-volume SMC (Sheet Moulding Compound) manufacturing was performed.

Challenge[edit | edit source]

The purpose of the project was to develop an enclosure to house the batteries for an electric powered vehicle. The goal was to minimize the cost and weight of the design. The design had to meet structural and thermal requirements including :

- Maximum deflection defined by the clearance between the battery enclosure lid and the top of the batteries.

- Minimum safety factors specified by the client for vertical, lateral, and acceleration g-force load cases (for more on safety factors, see Safety Factors - A363).

- Minimum safety factor specified by client for internal and external pressure load cases defined by the emergency pressure relief valve specifications.

- Minimum natural frequency to avoid resonance with the vehicle structure.

- Maximum stresses specified by the client in the adhesive of the bonded connections.

- Maximum tensile, shear, and bearing forces at the bolted connections.

- Survive a minimum number of fatigue cycles mimicking a duty load cycle.

- Survival in cold and hot temperature scenarios as defined by the client.

The materials and manufacturing method had to be appropriate based on the required volumes. Initially only a few battery enclosures were required for prototyping. Full-scale production required increased manufacturing output to meet the annual rate of 500 to 3000 units. Finally, the cost-benefit of investing in tooling and equipment for a high-volume production method of greater than 5000 units annually needed to be assessed as production volumes ramped up.

For more on product and manufacturing requirements see, Selecting Functional Requirements.

Approach[edit | edit source]

Metallic vs. Composite Assessment[edit | edit source]

At the start of the project, a design trade-off study was completed to evaluate the performance, cost, and weight of a metallic design and a composite design. The proposed composite design consisted of a one-piece tub with a separate lid. The attachment method to the vehicle was not fully designed, but it was anticipated that the tub would be bolted to the vehicle near the corners. The walls, floor, and lid of the metallic design were flat panels that consisted of thin cores sandwiched between metal sheets. These structures were supported by extrusions that ran along the length of each side. The metallic design was to be bolted to the vehicle using brackets at each corner.

During this initial assessment a finite element analysis (FEA) was performed on preliminary computer aided design (CAD) models. The models included the basic wall, floor, and lid geometry only. The batteries and their attachment method were not included in the model. Instead, the weight of the batteries was spread evenly across the floor of the enclosure. Additionally, the mounting hardware and weight of any electrical and mechanical subsystems attached to the enclosure were not included. Details such as the attachment method to the vehicle structure and sealing methods were also excluded. Instead, the structures were simulated with virtual adhesive interfaces to model the bonding behavior.

Only critical load cases such as the vertical gravity load and external lid load were included in the preliminary analyses. For each design the maximum deflection, skin stress, and core stress were evaluated.

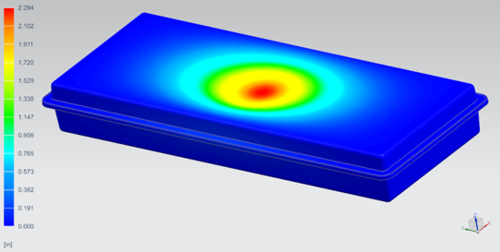

It was critical that the lid did not touch the batteries when deflected. However, the maximum height of the enclosure was limited based on clearance with other vehicle systems. These limitations defined the maximum allowable deflection. Figure 1 shows the initial deflection results for the external lid load applied to the composite design. The deflection exceeded the allowable limit, so the design was adjusted. In this case, a core material was added to the lid to make it stiffer. The analysis was repeated, revealing that the deflection had been reduced by over tenfold and now fell within the acceptable range.

A similar process was performed with the metallic design. In this case the original metallic design already included a core, but the deflection was twice as high as the final composite design because the face sheets were very thin. To decrease the deflection value, the density of the core was increased to improve the shear stiffness properties. This provided a lighter weight solution than increasing the metallic skin thickness. The density of the core was increased until the deflection was equivalent to the composite design. For more on cores see, Sandwich Panels.

The stresses in the composite plies and the metallic skins were also examined. For the composite design, it was discovered that the ply stresses were low, but no further optimization was feasible in order to maintain the part stiffness and not exceed the deflection limits. For the metallic design it was found the initial sidewall thicknesses resulted in a high safety factor, so the thicknesses were reduced to minimize the weight of the design.

The stresses in the core were also assessed. It was found that the safety factors in the cores for the composite design were high, but similar to the plies, no design optimization was possible in order to meet the deflection limits. The same thing was found to be true for the cores in the metallic design. The safety factors were high, but no adjustments were feasible due to the deflection limits.

Preliminary composite and metallic designs that met the deflection and stress limits were proposed at the conclusion of the design and analysis iterations. The mass of each design was estimated based on the material densities and part thicknesses. It was found that the composite design was approximately 10% lighter than the metallic design. The cost of each design was estimated by the client. They included the cost of raw materials, labour to build the individual components, and assembly labour. It was determined that the composite design was less expensive to produce because there were fewer components. This reduced the labour costs to build and assemble the parts. The upfront cost for the composite moulds was higher, but these costs could be amortized over the entire production run.

Production method and Detailed Design[edit | edit source]

Based on the weight and cost savings a decision was made to proceed with development of the composite design. It was anticipated that the production volume would be in the range of 500 to 3000 enclosures per year. Hand layup, resin infusion, RTM, and SMC manufacturing were considered. Based on the required volumes a resin infusion method was selected. The resin infusion method decreased labour costs compared to hand layup manufacturing. The cost of the tooling was more expensive, but the volumes were high enough that the tooling costs were small when amortized over the production run. The resin infusion process also resulted in a nicer interior surface finish than hand layup and provided a more consistent part thickness. This was important because the clearance between the lid and the top of the batteries was small. RTM and SMC were not selected because they required a large capital investment in equipment and tooling that was not economically justified based on the annual production volumes. It was also considered a riskier investment because this was the first time the client was using a composite battery enclosure.

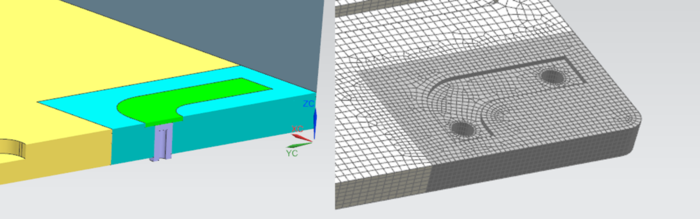

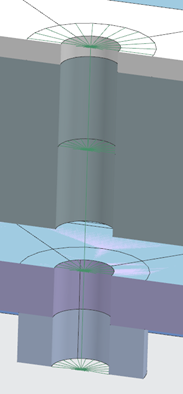

Once the manufacturing method was selected, a detailed design was created. A fibre mat was chosen that allowed resin flow during the infusion process. A core material and thickness were selected for the lid and for the bottom of the enclosure to increase stiffness as shown in Figure 2. Metal plates with external studs were integrated with the core in the bottom of the enclosure for battery mounting. Additionally, external metallic brackets were created to attach the battery enclosure to the vehicle. A combination of adhesives and bolts were selected for the mounting connections. An example setup of a bolted connection in the FE model is shown in Figure 3. A sealing system between the lid and the body of the enclosure with bolted connections was also created.

The FE model was updated with the new design, as well as new lateral acceleration, forward/aft acceleration, pressure, and temperature load cases. Results that were reviewed included deflection, and stresses in the composite plies, core, bolts, and adhesive.

Additionally, accelerometer test data from the vehicle was used to map out the duty cycle. This included the number of cycles for a given maximum acceleration and corresponding amplitude. These loads were entered into the model and the stress results were gathered. A Goodman diagram and a form of Miner’s rule as defined in Section 5.5.3.3 of the GL Guideline for the Certification of Wind Turbines [1] was used to combine the stress results for each acceleration level and confirmed the design could withstand the duty cycle over the lifetime of the vehicle. See Fatigue Factors for more information.

After the design was verified by FEA, prototype units were manufactured and field tested by the client. Upon successfully completing the field testing, the product was put into service.

Volume Ramp-Up and SMC Consideration[edit | edit source]

Over the span of three years a few thousand battery enclosures were successfully manufactured and placed into service. During this time the required volumes increased annually and were anticipated to grow further. The client did not have space or labour capacity in their existing facility to increase production rates. A project was launched to investigate alternative high-volume (greater than 5000 units annually) manufacturing methods. In particular, the use of Sheet Moulding Compound (SMC) manufacturing was examined (for more on SMC, look at Compression moulding - A302)

The study showed that moving to SMC manufacturing required numerous changes to the design. The first was the choice of material. The infusion glass fibre mats needed to be replaced by glass reinforced sheet moulding compound and a suitable resin selected. The percentage of glass fibre needed to be calculated, along with the required part thickness, to produce parts equivalent in stiffness and strength to the original infusion design. Another major change was the replacement of the cores in the lid and the base of the enclosure. The cores were included in the original design to increase stiffness in the part. However, the high pressures involved in the SMC process likely would have crushed the cores during processing. An alternative design that removed the cores and included ribbing was required. A change to the mounting plate for the batteries was also required to avoid damaging the studs under the high manufacturing pressures and to allow for easier replacement of the studs.

Changing to a SMC design would have required the manufacturer to invest in new capital equipment such as a hydraulic press. It also would have required building new metallic tooling that was estimated to be 6 to 10 times more expensive than the infusion tooling currently in production. However, cycle times would have been reduced by a factor of 8 or more when compared to the infusion process.

At the conclusion of the investigation, it was determined that the economic justification was not yet strong enough to switch to SMC manufacturing. Instead, the client was able to implement additional infusion manufacturing capacity at another location to meet the increased demand.

Outcome[edit | edit source]

Analysis of preliminary designs showed that the composite battery enclosure was both lighter and less expensive than the metallic counterpart. Based on volumes of 500 to 3000 units annually an infusion manufacturing method was selected that was less expensive than hand layup and resulted in more consistent part thickness, but avoided the high capital expenses of RTM or SMC. A detailed design was completed, which specified the material layups, attachment methods, and sealing requirements. Prototypes were built and field tested to prove the design was suitable. Subsequently, successful production of a few thousand enclosures using infusion processing was completed.

Switching to SMC manufacturing was evaluated in order to increase the production rate beyond 5000 units. It was determined that changes to the design to make it suitable for SMC processing could be implemented successfully. However, upon evaluation of the capital equipment and tooling costs it was decided that the volumes were not yet sufficient to economically justify the change in manufacturing processes.

References

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.