How Composites Differ From Metals - A342

Introduction[edit | edit source]

In this document, a comparison between composites and metals will be provided, along with example applications. A case study on glass fibre composite window lineals and doors is provided showing how composites can provide a benefit compared to traditional building materials such as aluminum.

Background[edit | edit source]

Composite materials offer unique benefits compared to metals. These include corrosion resistance, high strength to weight ratio, and the ability to tailor the material properties to specific applications. However, there are some properties of composite materials which are detrimental to some applications when compared with metal structures. Understanding the differences between composites and metals is important to select appropriate materials for specific applications.

Application[edit | edit source]

Composite materials have a number of differences from metals that can be beneficial for specific applications. Some key differences between composites and metals are outlined below.

Directional Properties[edit | edit source]

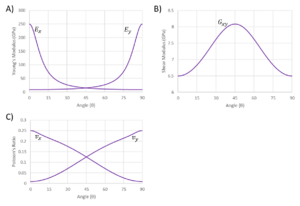

Unlike metals which are isotropic materials, meaning their properties are the same in all directions, the strength and stiffness of composite materials comes from oriented fibre. This results in composite materials having different properties in different directions. In situations where loading directions on a part are well understood, this directionality of properties can be taken advantage of to optimize a structure in ways that a standard metallic structure cannot. However, in situations where loading conditions are not well understood and a component is required to have similar properties in all directions the potential optimization benefits of composite materials may not be fully realized. See figure for an illustration of how the properties of fibre change with the angle of loading.

Strength Related to Weight[edit | edit source]

Composites have superior strength properties per unit mass compared to metals, in particular steel, where significant weight advantages can be achieved by converting parts from steel to composite. The maximum benefit comes when composites are designed to closely align fibre in the direction of load paths around a structure. The ability to build up layers of material and orient the fibre in the individual layers allows parts to be engineered for specific applications. This amount of design freedom is not possible with metals. Glass and carbon reinforced plastics have a density about 60-70% that of aluminum, or about 20% that of steel.

Corrosion Resistance[edit | edit source]

A key benefit of using composites compared to steel and aluminum is the improved corrosion resistance to salts and chemicals. Examples of applications that make use of this are chemical storage tanks, glass fibre rebar and boat hulls. In applications where corrosive environments are present in addition to cyclic loading, composites can provide benefits by not being susceptible to stress corrosion cracking.

Design Flexibility[edit | edit source]

Composites allow complex curvature that would otherwise be expensive to achieve with metals. There are however limitations with the ability of composite materials to achieve some geometry typical of machined, cast or stamped metallic components. This includes items such as draft requirements to allow composites to demould, minimum radii due to conformability restrictions of composite fibre reinforcements and limitations on fine detail. In general a component should be designed from the start as either a composite or metallic component, keeping in mind strengths and weaknesses of the materials and manufacturing methods throughout the design and development process. Composites can also utilize multiple types of fibre can be included within a single part to tailor specific performance aspects.

Nonconductive[edit | edit source]

Many composites do not conduct electricity, and so can be used in applications such as electronics and electrical utility poles. In some applications such as aircraft components in lightning strike zones this is not advantageous and additional conductive material must be included within the composite layup to improve survivability.

Nonmagnetic[edit | edit source]

Composites are not magnetic, and so can be used for applications such as MRI (magnetic resonance imaging) and other sensitive electronic equipment.

Radar/EM Transparent[edit | edit source]

Composite materials do not respond to Radar in the same way as metals, and so are used in large quantities in stealth military aircraft. In additional there are many radome and other applications requiring signal transparency or limited loss that are more suitable for composites than metals. In some situations the lack of signal loss through a composite is detrimental to the application and additional metallic EM shielding is added to a composite component to protect other components from interference. This is common practice in composite aircraft components that act as a barrier for sensitive equipment.

Low Thermal Conductivity[edit | edit source]

Composites have low thermal conductivity, and so can improve thermal performance of building materials such as window lineals, doors, etc. To continue reading about conductivity visit Thermal conductivity.

Properties Created During Part Manufacturing[edit | edit source]

A key difference between composite materials and metals is that for composites the material properties and performance are created during manufacture of a component. The impact of this is that the design of a composite component cannot be successfully completed without a sound understanding of material and process limitations. In addition there is a lack of standardized materials with known properties that can be applied across multiple designs in the same way that many metals can be utilized. The ability to achieve mechanical properties from a composite material is very dependent on capabilities of the part fabricator and correct application of materials from the designer with processing limitations in mind. To read more about the properties of composites visit Composite properties.

Practice (Case Studies/Examples)[edit | edit source]

Glass Fibre Lineals[edit | edit source]

Glass fibre lineals have seen an increased usage in window and door applications when consideration is made for energy efficiency. Aluminum extrusions have commonly been used to create window and door frames however the high thermal conductivity can result in significant heat loss in residential or commercial applications. The utilization of glass fiber lineals as an alternative provides improvements in energy efficiency due to reduced heat loss as well as the potential for longer-lasting window seals as a result of having a closer coefficient of thermal expansion between the window and glass fiber frame than would be observed with an aluminum frame.

Conclusion and Further Information[edit | edit source]

Composites provide many benefits compared to traditional materials, and in particular metals. The main benefits compared to metals are: increased strength related to weight, corrosion resistance, design flexibility, non-conductivity, nonmagnetic, radar transparent and low thermal conductivity. However, these benefits are only realized with a good understanding of composites and careful design.

Return to Fundamentals of composite materials[edit | edit source]

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.