Fundamentals of composite materials - A100

Overview[edit | edit source]

What is a composite material?

A composite material is a combination of two or more materials of distinctly different chemical or physical characteristics. Working together in collaboration, they create a new material combination of enhanced properties and characteristics that neither material on its own can provide.

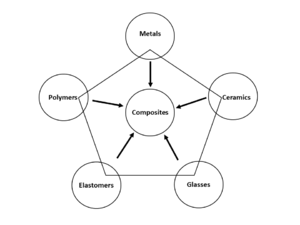

As a newly created material capable of unique properties and characteristics, composites are generally accepted as an additional class of the engineering materials.

Classes of Engineering Materials:

- Metals

- Polymers

- Ceramics

- Composites

While the combinations of materials are limitless, the Knowledge in Practice Centre (KPC) primarily focuses on material combinations of polymers reinforced with fibres of various materials. Often referred to as fibre reinforced polymers (FRPs), these include the commonly-known glass fibre and carbon fibre (composite) materials.

What are the advantages of composite materials? The material properties achieved by purposeful material combinations can give composites advantages that cannot be achieved by conventional single engineering materials. Advantages may be high stiffness or strength to weight ratio (think airplane or race car), tailorable stiffness or high elastic storage modulus in defined load directions (think kayak paddle or hockey stick).

Where are composite materials used? Composite materials are used in a wide range of applications from aerospace structures, to boat hulls, to sporting goods. For example, composite materials enable us to fly further and develop more fuel-efficient automobiles (vehicle weight reduction), harvest energy more efficiently (lighter and larger wind turbine blades), prevent injury (safety equipment like motorcycle helmets), and enjoy recreational activities (sporting equipment).

Composites market:

- Aerospace

- Automotive

- Sporting goods

- Marine

- Consumer goods

- Construction/civil structures

- Industrial applications

Learn more, view KPC AIM Event webinar:

History of Composites[edit | edit source]

Origins of composite materials[edit | edit source]

The use of composite materials dates back to ancient Egypt, Turkey, and Mesopotamia, where civilizations combined natural materials such as straw to reinforce mud and clay in bricks and pottery. The concept of a laminated structure making use of fibre orientations is also suggested to have originated in ancient Egypt in 3400 BCE in the form of plywood. In the 1200s, the Mongols were credited as having developed the first composite bow, using a sandwich structure made of animal bone, ligaments, wood, pine resin, and other natural materials[3].

1900s[edit | edit source]

Modern day, advanced composites are relatively new with their history originating in the early 1900s with the development of artificial plastics and thermosetting resins such as Bakelite in the USA. In 1913, the concept of pre-impregnation was filed in a patent and in 1916 another patent was filed for a composite airplane propeller. It wasn't until the 1930s, however, with the first industrial processes for making glass fibres, that fibre reinforced polymers (FRPs) were born. World War II promoted the production of FRPs, which led to the introduction of glass fibre reinforced polymers (GFRPs) being used in airplanes, automobiles, boat hulls, and even surfboards. In the late 1950s and early 1960s carbon and aramid fibres were introduced to the world, with breakthroughs in research occuring in the USA, UK, and Japan[3][4]. This has since revolutionized the composites industry. Owing to their attractive strength-to-weight properties, the aerospace industry began adopting carbon fibre reinforced polymers (CFRPs) and has since led in the advancement of composite material design and manufacturing.

Modern day[edit | edit source]

In 2009, Boeing unveiled the 787 Dreamliner, a commercial airliner comprising of 80% composites by volume. Today, composite materials have found use in a wide range of markets from specialized applications to consumer products.

Composites market:

- Aerospace (airplanes, space launch vehicles)

- Automotive (automobile bodies, panels, beams)

- Sporting goods (skis and snowboards, helmets, hockey sticks, bicycles, fishing poles)

- Marine (boat hulls)

- Consumer goods (computer and cellular phones)

- Construction/civil structures (bridges)

- Industrial applications (electrical insulators, piping)

Main Constituents of a Composite Material[edit | edit source]

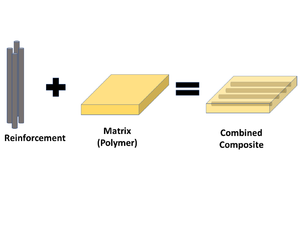

Composite materials are formed by combining two material parts or components, referred to as constituents:

- Reinforcement material (the load bearing material) - generally stiffer and stronger

- Matrix material (the binding / hold everything together material) - generally less stiff and weaker

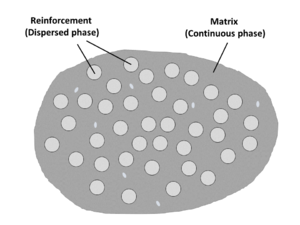

The two materials comprised together in the form of a composite material, where the matrix is the continuous material phase, while reinforcement is the dispersed material phase. The matrix material component is used to classify the type or family of the composite material.

Broadly speaking, there are three main families of composite materials:

- Polymer matrix composites (PMC) – the focus in the KPC

- Metal matrix composites (MMC)

- Ceramic matrix composites (CMC)

The typical industry naming convention for composite materials makes reference to both the reinforcement and the matrix material constituents. For example, fibre reinforced polymer (FRP) refers to fibre reinforcement form, and polymer matrix. More detailed naming examples include glass fibre reinforced polymer (GFRP) – often just referred to as glass fibre (or fibre glass) composite, and carbon fibre reinforced polymer (CFRP) – referred to as carbon fibre composite; indicating the reinforcement material and form, and matrix material class respectively.

How the reinforcement and matrix material components are combined together to form the composite material is the subject matter of composites processing. See here for some common industry composite manufacturing process examples.

For further material information than of what is provided on this page, see the Material Structure page in the Foundational Knowledge volume.

Reinforcement material[edit | edit source]

Link to Reinforcement Structure on the Material Structure page in Foundational Knowledge

The reinforcement component is responsible for the main load bearing capability in the composite material. Reinforcements can range from short discrete particles to long continuous fibres and woven fibre fabrics. Because of their load bearing function, reinforcement material are generally ceramic class materials, or high strength synthetic polymers.

In fibre reinforced polymers (FRPs), popular fibre materials include:

| Ceramic materials | Polymer materials |

|---|---|

| Glass fibre | Aramid fibre (e.g. Kevlar) |

| Carbon fibre | Ultra-high-molecular-weight polyethylene fibre (e.g. Spectra) |

For more information on reinforcement material choice, see the catalogue volume reinforcement material page.

Matrix material[edit | edit source]

Link to Matrix Structure on the Material Structure page in Foundational Knowledge

The function of the matrix component is to bind together the reinforcement, to aid in the load transfer between the reinforcement, and to hold the combined composite material in the desired part shape. Other functions of the matrix include protecting the reinforcement from the environment, and depending on the reinforcement form – supporting the reinforcement in compression (e.g. fibre reinforcement).

Desirable characteristics of the matrix material:

- low density (for lightweight composite material)

- environmental resistance: chemical, moisture resistant

- processible: able to flow and surround the reinforcement material during the manufacturing process

In fibre reinforced polymers (FRPs), the polymer makes up the matrix constituent. Both thermoset and thermoplastic polymers can be used as matrices.

Examples of popular polymer matrix materials:

| Thermoset materials | Thermoplastic materials |

|---|---|

| Epoxy | Polyproplyene (PP) |

| Vinyl ester | Polyether imide (PEI) |

| Polyester | Polyether ether ketone (PEEK) |

For more information on popular matrix materials, see the catalogue volume matrix page.

Laminate construction[edit | edit source]

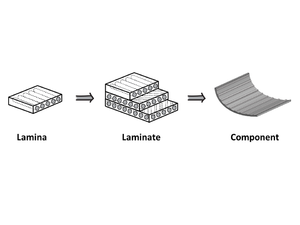

When constructing FRP composite materials using long continuous fibre reinforcements, typically sheets of the reinforcement fibre material are stacked to form a laminate structure - giving rise to the commonly used terms of composite laminate, and lay-up. Using this laminate construction technique, the fibre orientations can be varied at each layer for a more efficient handling of the mechanical load through the material. See for the Material Structure page (Foundational Knowledge volume) for further explanation.

Composite Design and Manufacturing[edit | edit source]

Link to main Composite Design and Manufacturing page

Composites manufacturing practice is driven by the need to achieve a desired manufacturing quality, which in turn is governed by the manufacturing science. On one side, there exists the knowledge (science) base which defines 'why' the quality is as it is. On the other side, there is the practice of 'how' best to implement manufacturing processes to affect the quality in a given way. The interconnectivity and understanding of these two elements are important and form the basis of knowledge-in-practice thinking[5].

On the composite design and manufacturing page, you will find a general overview about the composite design and manufacturing practice.

Composite Processing and Manufacturing[edit | edit source]

Link to main Composites Manufacturing page

A composite manufacturing process is a collection of process steps transforming the raw material reinforcement and resin matrix constituents into a combined composite material of a desired part shape and geometry. The processing impacts both the final material properties and resulting part component performance. It also crucially determines the associated component production rate and production costs.

For examples of common composite manufacturing processes, see here (Composites Manufacturing - Common Process Examples).

In the KPC, we present a systematic approach to defining the manufacturing process. Specifically, we promote the idea that a process is nothing more than a set of equipment and tooling used to perform a specific action (or process step) on the part or material. Therefore, the manufacturing workflow is dictated by the steps performed by equipment and tooling.

Learn about the CKN Knowledge in Practice Centre approach to systems approach to composites here.

Explore this area further

References

- ↑ [Ref] Ashby, M.F. (2011). Materials Selection in Mechanical Design. Elsevier. doi:10.1016/C2009-0-25539-5. ISBN 9781856176637.CS1 maint: uses authors parameter (link) CS1 maint: date and year (link)

- ↑ [Ref] Callister, William D. (2003). Materials Science and Engineering: An Introduction. John Wiley & Sons, Inc. ISBN 0-471-13576-3.CS1 maint: uses authors parameter (link) CS1 maint: date and year (link)

- ↑ 3.0 3.1 [Ref] Verpoest, Ignaas (2020). 50 Years of Composites: Past Present & Future.CS1 maint: uses authors parameter (link) CS1 maint: date and year (link)

- ↑ [Ref] Nagavally, Rahul Reddy (2016). "Composite Materials - History, Types, Fabrication Techniques, Advantages, and Applications". 5 (9). ISBN 9789386083692. Cite journal requires

|journal=(help)CS1 maint: uses authors parameter (link) - ↑ [Ref] Fabris, Janna Noemi (2018). A Framework for Formalizing Science Based Composites Manufacturing Practice (Thesis). The University of British Columbia, Vancouver. doi:10.14288/1.0372787.CS1 maint: uses authors parameter (link)

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.