Flow sensors - A223

| Flow sensors | |

|---|---|

| Document Type | Article |

| Document Identifier | 223 |

| Relevant Class |

Equipment |

| Tags | |

| Factory Cells | |

| Prerequisites | |

Introduction[edit | edit source]

Flow sensors are devices that are used to measure the the flow of liquids or gases in a variety of applications in composites manufacturing processes.

Scope[edit | edit source]

This page covers the fundamentals of flow sensors commonly used in composites processing/manufacturing. It discusses different types of sensors, examples of use cases for each, and the advantages and disadvantages associated with them.

Significance[edit | edit source]

Flow sensors are used in different stages of composites manufacturing processes. They are used to monitor and control the flow of resin in liquid composite moulding processes. They can also be used to characterize the airflow in manufacturing equipment like ovens and autoclaves, to get an understanding of the airflow patterns and consequently, the heat transfer coefficients (HTCs).

Prerequisites[edit | edit source]

Recommended documents to review before, or in parallel with this document:

Overview[edit | edit source]

There are two basic categories of flow sensors:

- Liquid flow sensors: These are used to monitor and control the flow of resin in processes like resin transfer molding (RTM) and vacuum assisted resin infusion (VARI) [1][2].

- Gas flow sensors: These are used to measure and characterize the airflow in processing equipment like autoclaves and ovens. The airflow analysis inside equipment can help in understanding expected range of processing parameters like heat transfer coefficients (HTC) which are a crucial component of designing cure processes for highly reliable autoclave-based composite manufacturing processes[3].

Types of liquid flow sensors[edit | edit source]

Optical fiber flow sensor[edit | edit source]

An optical fiber flow sensor detects the flow of a liquid based on the propagation of light along an optical fiber based on total internal reflection. They can be used to detect the flow front of a resin during an infusion process for example. Depending on the refractive indices of the process fluid, the loss of the optical fiber will generally increase with the fiber being increasingly covered by the liquid.

Dielectric sensors[edit | edit source]

Dielectric sensors can be used to detect the flow front of a liquid based on the change in the electrical properties of a preform as the resin impregnates it. These sensors are integrated into the part and can also be used to monitor the progress of cure after the infusion has been completed.

Types of gas flow sensors[edit | edit source]

Hot-wire anemometers[edit | edit source]

A hot-wire anemometer is a thermal transducer which can be used to measure instantaneous flow velocity. It works on the principle of forced convective heat transfer from the tip of the anemometer wire. The wire is heated due to a small amount of current passing through it, which is then lost to the surrounding gas flowing due to convection. The loss of heat can be calibrated to measure the velocity of the flowing gas.

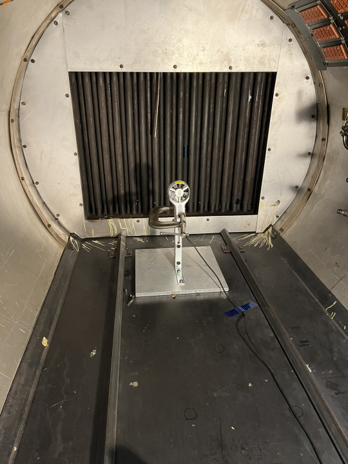

Vane anemometers[edit | edit source]

A vane anemometer can be used to measure the flow of gases by conversion of mechanical energy to electric signals. It consists of a small turbine with rotating blades which are connected to an electrical circuit. The flow of gases around the anemometer spins the blades and the mechanical energy can be converted to an electrical signal. The electrical signal can be calibrated to estimate the velocity of the flowing medium around the anemometer.

Comparison of different sensors[edit | edit source]

The advantages and disadvantages for the different sensors can be compared as:

| Sensor Type | Advantages | Disadvantages | Typical cost |

|---|---|---|---|

| Optical fiber flow sensor |

|

|

~10$ |

| Dielectric flow sensors |

|

|

Depends on size and material |

| Hot-wire anemometers |

|

|

~1000 - 2000 $ |

| Vane anemometers |

|

|

~40 - 800 $ |

In composites manufacturing processes, flow sensors are used both in the design of process cycles as well as in-process control. Depending on the particular application, different sensors can be used. For example, to track the progress of an infusion process accurately, dielectric sensors can be embedded in sacrificial zones of laminates. On the other hand, when designing process cycles, vane anemometers can be used to understand the airflow patterns inside autoclaves and ovens

References

- ↑ [Ref] Liebers, Nico et al. (2015). Autoclave Infusion of Aerospace Ribs Based on Process Monitoring and Control by Ultrasound Sensors (published 22 July 2015). Retrieved 3 December 2024.CS1 maint: extra punctuation (link) CS1 maint: uses authors parameter (link) CS1 maint: date and year (link)

- ↑ [Ref] Tuloup, C. et al. (2019). "On the use of in-situ piezoelectric sensors for the manufacturing and structural health monitoring of polymer-matrix composites: A literature review". 215. doi:10.1016/j.compstruct.2019.02.046. ISSN 0263-8223. Cite journal requires

|journal=(help)CS1 maint: extra punctuation (link) CS1 maint: uses authors parameter (link) - ↑ [Ref] Slesinger, Nathan et al. (2010). Simple Visualization of Autoclave Airflow Using Wireless Cameras. Society for the Advancement of Material and Process Engineering.CS1 maint: extra punctuation (link) CS1 maint: uses authors parameter (link) CS1 maint: date and year (link)

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.