Temperature Sensors - A221

| Temperature Sensors | |

|---|---|

| Document Type | Article |

| Document Identifier | 221 |

| Themes | |

| Relevant Class |

Equipment |

| Tags | |

| Factory Cells | |

| Prerequisites | |

Introduction

Temperature sensors are devices that are used to measure the temperature of a part. Most temperature sensors work on the principle of detecting changes in temperature by measuring changes in other physical parameters that are effected by temperature changes, such as voltage or resistance.

Scope

This page covers the fundamentals of temperature sensors commonly used in composites processing/manufacturing. It discusses different types of sensors, examples of use cases for each, and the advantages and disadvantages associated with them.

Significance

The mechanical and chemical properties of a material depend on the thermal history during processing. Hence, to get a better understanding of the thermal history of a material during processing, temperature sensors are frequently used for data collection. In composites manufacturing, temperature sensors are essential for monitoring the temperatures of the parts during curing processes. An accurate measurement of temperature during these processes is essential for certification in industries such as aerospace.

Prerequisites

Recommended documents to review before, or in parallel with this document:

Overview

There are two basic categories of temperature sensors:

- Contact Sensors: These sensors must be in physical contact with the object being measured and can be used to measure the thermal history of solids, liquids, and gases over a wide range of temperatures.

- Non-contact Sensors: These sensors interpret the radiant energy emitted by an object as infrared energy within the electromagnetic spectrum. Widely used in hazardous environments, these devices are effective for monitoring non-reflective solids and liquids but tend to be less accurate with gases, primarily due to their low density.

There are four types of sensors that are widely used in measuring temperatures, each with their own use cases:

- Thermocouple

- Thermistor

- Thermal camera (infrared, IR)

- Resistance Temperature Detector (RTD)

Types of temperature sensors

Thermocouples

Thermocouples are a type of temperature sensor that uses principles of the Seebeck (thermoelectric) effect to measure temperature. It is simply a junction of two wires composed of different metals with different thermoelectric properties. This junction creates a voltage that is a function of the temperature at the junction. The voltage can be measured and correlated to the temperature of the junction using the Seebeck effect.

The Seebeck effect describes the resultant thermoelectric voltage \(E\) developed between two points in a conductor or semi-conductor due to a temperature difference \(ΔT\) between those two points [1]. The Seebeck coefficient \(\alpha\), defined as the thermoelectric voltage developed per unit temperature difference, can be expressed as:

\(E = \alpha \Delta T \)

where:

\(\alpha \) = Seebeck coefficient, [V/K],

\(E\) = Voltage [V], and

\(T\) = Temperature [K],

See: Thermocouple for more information.

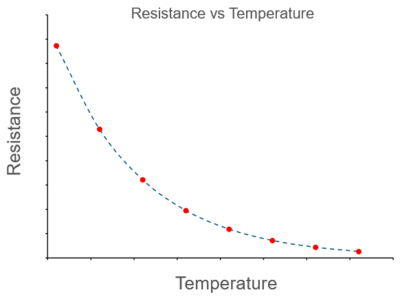

Thermistor

A thermistor is a temperature sensor which operates on the principle that the resistance of a material changes with temperature. There are two types of thermistors: NTC (Negative Temperature Coefficient) and PTC (Positive Temperature Coefficient) [2]. In NTC thermistors, resistance decreases as the temperature increases, whereas in PTC thermistors, resistance increases with rising temperature.

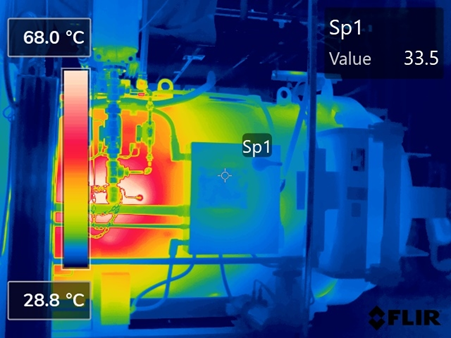

Thermal Camera

Thermal cameras are a type of non-contact sensors which operate based on the principle that all objects emit infrared radiation if their temperature is above absolute zero temperature [3]. The most commonly used type of thermal camera is equipped with an infrared focal plane array (IRFPA), which captures this radiation and produces a two-dimensional image.

There are generally two categories of detectors in thermal cameras:

- Photon Detectors: These detectors convert absorbed electromagnetic radiation directly into changes in electronic energy distribution within a semiconductor. This occurs through alterations in the concentration of free charge carriers.

- Thermal Detectors: These devices capture electromagnetic radiation and convert it into thermal energy, which then causes a rise in the detector’s temperature. The thermal energy is subsequently converted into an electrical output by exploiting changes in a physical property of the material, such as the temperature-dependent electrical resistance found in a bolometer.

Resistance Temperature Detector (RTD)

A Resistance Temperature Detector (RTD) measures the changes in temperature by correlating changes in electrical resistance. Unlike thermistors, which use semiconductor materials, RTDs use pure metal wires, typically platinum or copper. These metals consistently show an increase in resistance with temperature. RTDs are known for their linear response to temperature changes but are less sensitive compared to the highly sensitive and non-linear thermistors.

Comparison of different sensors

The advantages and disadvantages for the different sensors can be compared as:

| Sensor Type | Advantages | Disadvantages | Typical cost |

|---|---|---|---|

| Thermocouple |

|

|

~10$ |

| Thermistor |

|

|

~30$ |

| Thermal camera |

|

|

~15,000$ |

| Resistance Temperature Detector (RTD) |

|

|

~300$ |

In composites manufacturing processes, temperature sensors are used both in the design of process cycles as well as in-process control. Depending on the particular application, different sensors can be used. For example, to measure the part temperatures accurately, thermocouples are often embedded in sacrificial zones of laminates to accurately measure the temperature of the material during curing. On the other hand, when full field temperature measurements are required, thermal cameras are typically used.

This page links to:

Explore this area further

References

- ↑ [Ref] Iwanaga, Shiho et al. (2011). "A high temperature apparatus for measurement of the Seebeck coefficient". 82 (6). AIP Publishing. ISSN 0034-6748. Cite journal requires

|journal=(help)CS1 maint: extra punctuation (link) CS1 maint: uses authors parameter (link) - ↑ [Ref] Feteira, Antonio (2009). "Negative temperature coefficient resistance (NTCR) ceramic thermistors: an industrial perspective". 92 (5). Wiley Online Library. ISSN 0002-7820. Cite journal requires

|journal=(help)CS1 maint: uses authors parameter (link) - ↑ [Ref] Gade, Rikke; Moeslund, Thomas B (2014). "Thermal cameras and applications: a survey". 25. Springer. ISSN 0932-8092. Cite journal requires

|journal=(help)CS1 maint: uses authors parameter (link)

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.