Manual Cutting Tools for Prepreg - A402

| Manual Cutting Tools for Prepreg | |

|---|---|

| Document Type | Article |

| Document Identifier | 401 |

| Tags | |

| Prerequisites |

|

Introduction[edit | edit source]

This page further provides some of the best practices associated with the hand cutting of prepregs. Particularly referencing the tools used for this process. This is important, as even in factories and processes using automated fiber cutting methods, some amount of hand cutting may still be necessary.

Significance[edit | edit source]

This is important, as even in factories and processes using automated fiber cutting methods, some amount of hand cutting may still be necessary.

Scope[edit | edit source]

This page provides some general considerations when using manual cutting tools, including Olfa™ Knifes, X-ACTO™ Knifes, and shears when cutting prepreg materials.

Razor Knife cutting Tools[edit | edit source]

Razor knifes are very commonly used to cut prepreg materials. This is the cheapest way to cut these materials, however present significant challenges. Productivity is the lowest using a razor knife. It is also the most difficult to achieve higher accuracies (when cutting complete plies). The knife blade can also disturb the weave if a proper cutting technique is not used or the blade is not clean and/ or worn/dull. A slip of the knife can also result in material wastage and possible personnel harm. Hand cutting with a razor knife should be performed by a properly trained and experienced operator to avoid the many potential pitfalls. Cut resistant gloves made from materials like Kevlar®, Dyneema® or HPPE maybe be worn to protect workers.

Routine inspection of the blade is required to prevent resin buildup, which could result in damaging plies while cutting. Replace the knife blade by either breaking off the end blade or removing and replacing it with a new one. Follow the proper procedure to replace the blade. When cutting, trimming or replacing a blade, care should be taken to not have residual parts become FOD. Care should also be taken to avoid injury in the blade replacement process. Blades are typically disposed of in a 'sharps container', which is a receptacle designed to keep sharp items safe while being disposed of.

Safety is an important aspect to cutting with a knife. Wherever possible, safety glasses, cut resistant “slash gloves” and any other proper PPE should be used when using knives. Cutting in line with hands and body should be avoided. Utmost care should be taken when using razor knives. Other personal safety considerations include:

- Hold the knife firmly

- Minimize the amount of blade exposed (ie. retract to the minimum required length)

- Dispose of knife blade in proper disposal receptacles (sharps containers)

- Do not operate tools until properly trained

Cutting plies with a razor blade knife directly on the tool or over another ply is a dangerous practice. The ply to be cut should be lifted off the surface below to ensure the knife blade does not damage the layer underneath. When a ply is trimmed, if a ply is cut underneath, the overall strength of the part is compromised and greatly reduced. This can be an extremely serious matter if one of these components should be mounted on an aircraft, satellite, etc. and loses its structural integrity. Also, cut marks in the tooling greatly affect the surface of the finished part, which in turn, will result in more time being spent sanding and filling the part. Cut marks in tool may also cause delamination and vacuum leaks in the layup tool, which require a substantial amount of worker-hours and materials to rectify. Damage of this nature has frequently rendered tooling useless until properly repaired and has greatly reduced the life expectancy of many lay up tools. Therefore, the cutting of plies directly on the tool should be prohibited, and the proper cutting and trimming methods during lay up are to be followed.

Proper Cutting Technique with Razor Knifes[edit | edit source]

- Lift the material to be cut from the underlying ply or tool to avoid damaging them with the cutting tool.

- Hold the knife firmly in your hand, minimize the amount of blade sticking out, and avoid cutting in line with hands and body.

- Start the edge with a cutting motion of the blade to minimize fibre disturbance at the material edge and avoid damaging the surface below.

- Guide the knife along the traced line, pulling up gently with the other hand so that the razor blade glides through the material. If it snags, a slight cutting motion should restart the cutting process. If not, the blade may need cleaning or replacement.

- Ensure loose cut off pieces do not become Foreign Object Debris (FOD).

- Cut accurately, following the desired path as closely as possible. Also erroring on the outside edge to avoid damaging the ply. Smaller, trim cuts with a razor knife or scissors can follow if required.

- Cleanliness and usage of the knife. Soft (paper, Sepia or other) and/or hard (plastic or carbon) templates can be built to mark a cut line. In general these should be used to mark the surface to cut, not to cut against as the cutting tool may damage the template or result in FOD in the material. Most cutting is done on a flat table in 2D to provide the most accuracy.

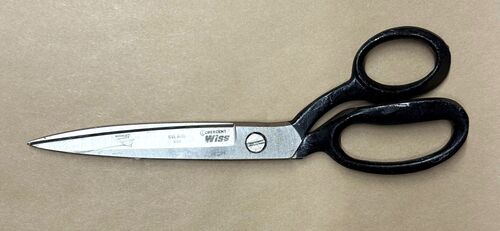

Scissors[edit | edit source]

They must be maintained with regular cleaning and sharpening. Where permitted, scissors can be kept in a solvent suitable to the resin to keep prepreg epoxy from building up on the scissors and impeding cutting. The scissors should be carefully wiped of cleaning agents to avoid affecting the prepreg epoxy.

Considerations when using Scissors[edit | edit source]

- Scissors should be the main tool for manual trimming (over a razor knife).

- Need to develop ability to reach tight spots.

- Use caution to not damage a laid up ply or tooling.

- Scissors require routine cleaning and sharpening as necessary.

- Use by cutting away from your body in regular strokes.

- Pass scissors handle first.

- Do not attempt to catch a dropped pair of scissors.

- Only use scissors for their intended cutting purpose. (Trim, Fibre cutting, Ply cutting)

- Do not run or climb while carrying a pair of scissors

| About | Help |

Welcome

Welcome to the CKN Knowledge in Practice Centre (KPC). The KPC is a resource for learning and applying scientific knowledge to the practice of composites manufacturing. As you navigate around the KPC, refer back to the information on this right-hand pane as a resource for understanding the intricacies of composites processing and why the KPC is laid out in the way that it is. The following video explains the KPC approach:

Understanding Composites Processing

The Knowledge in Practice Centre (KPC) is centered around a structured method of thinking about composite material manufacturing. From the top down, the heirarchy consists of:

- The factory

- Factory cells and/or the factory layout

- Process steps (embodied in the factory process flow) consisting of:

The way that the material, shape, tooling & consumables and equipment (abbreviated as MSTE) interact with each other during a process step is critical to the outcome of the manufacturing step, and ultimately critical to the quality of the finished part. The interactions between MSTE during a process step can be numerous and complex, but the Knowledge in Practice Centre aims to make you aware of these interactions, understand how one parameter affects another, and understand how to analyze the problem using a systems based approach. Using this approach, the factory can then be developed with a complete understanding and control of all interactions.

Interrelationship of Function, Shape, Material & Process

Design for manufacturing is critical to ensuring the producibility of a part. Trouble arises when it is considered too late or not at all in the design process. Conversely, process design (controlling the interactions between shape, material, tooling & consumables and equipment to achieve a desired outcome) must always consider the shape and material of the part. Ashby has developed and popularized the approach linking design (function) to the choice of material and shape, which influence the process selected and vice versa, as shown below:

Within the Knowledge in Practice Centre the same methodology is applied but the process is more fully defined by also explicitly calling out the equipment and tooling & consumables. Note that in common usage, a process which consists of many steps can be arbitrarily defined by just one step, e.g. "spray-up". Though convenient, this can be misleading.

Workflows

The KPC's Practice and Case Study volumes consist of three types of workflows:

- Development - Analyzing the interactions between MSTE in the process steps to make decisions on processing parameters and understanding how the process steps and factory cells fit within the factory.

- Troubleshooting - Guiding you to possible causes of processing issues affecting either cost, rate or quality and directing you to the most appropriate development workflow to improve the process

- Optimization - An expansion on the development workflows where a larger number of options are considered to achieve the best mixture of cost, rate & quality for your application.

To use this website, you must agree to our Terms and Conditions and Privacy Policy.

By clicking "I Accept" below, you confirm that you have read, understood, and accepted our Terms and Conditions and Privacy Policy.